The most important building materials are discussed in this article that you need to be aware of when designing and constructing buildings.

Many naturally occurring materials such as clay, sand, rock, wood, etc. are used as building materials in addition to man-made materials such as structural steel, reinforcements, concrete, brick, aluminum, etc.

The use of the construction materials depends on the nature of the structure to be built. Let’s discuss the construction materials in detail by taking them one by one.

Concrete as Building Material

Concrete is the most widely used construction material. It is also used as one of the most common building materials. Whether the building is constructed from structural steel, we have used concrete to construct the foundation.

Unless the structure foundation is made of steel or timber, all other structures’ foundations would be made from concrete or reinforced concrete.

Concrete is made of cement, aggregate, and water. In addition, we add admixtures to improvise various performances of the concrete. Based on the strength and durability of concrete requirements, the grade of the concrete is selected. The grade of the concrete represents the characteristic strength of concrete. The mix proportion of the cement, aggregate (fine aggregate; sand for manufactured sand and coarse aggregates), and water produce the different grades of concrete.

Concrete Admixtures such as retarders, water reducers, superplasticizers that include high range water reduces, etc are used to modify the behavior of the concrete. Setting time of concrete, workability of concrete, etc. are modified with the admixtures.

Fresh concrete pouring is done into the area where the structure is to be built. Checking setting out, formwork, reinforcement, cleaning, etc. are done before the pouring of concrete. Special attention shall be made when concreting is larger.

With the increase of thickness of concrete, the heat produced as a result of the heat of hydration increases significantly. Therefore, necessary measures shall be taken to avoid cracking of concrete due to the heat generated in the hydration process and service. Further, attention shall be made to the formation of delayed ettringite due to the rise of the temperature abnormally. In general, the rise of the temperature in the hydration process is limited to 700C.

Once concrete is poured, rapid drying of concrete shall be avoided. It directly affects the durability of the structure. The curing of concrete is done to produce a strong cover zone and to avoid cracking of concrete.

Before the pouring of concrete and after the pouring of concrete, concrete testing is done to make sure the expected workability and strength of the concrete are available.

- The concrete sump Test is done to check the workability of concrete at the site before pouring.

- Concrete cube tests or cylinder tests are done to check whether the concrete has the characteristic strength specified in the mix design.

Concrete is a composite material and its strength increases with the addition of the other construction materials. Concrete is weak in tension and we add reinforcement or materials like fiber to improve the tensile capacity. Further, concrete acts together with reinforcement when resisting the applied loads.

Steel as Building Materials

Same as concrete, steel is also one of the building materials used most often in construction. The steel used for the construction can be categorized based on the purpose of using them.

- Reinforcements Steel or Rebar

- Structural Steel

Reinforcement Steel as Building Materials

Unless it is mass concrete, we provide the reinforcement to carry the ultimate limit stage loads and protect the structure from serviceability requirements.

Reinforcement is also called the rebar. It is the most vital material used in structures to carry the tensile stress. Concrete weak in tension. The tensile capacity or allowable tensile stress of concrete is about 10% of its compressive strength. In the area where there are tensile stresses, we provide reinforcement to carry the load. In addition, reinforcement is provided to improve the structural capacity of the concrete.

Reinforcement has two main categories. They are mid steel and tor steel. The tor steel now has been developed to rib steel(TMT bars) having higher tensile strength and yield strength. There are reinforcements having yield strength 500-650N/mm2 produced presently. The modern improvement of the reinforcement has been made by the Thermo-Mechanical Treatment. Therefore, these bars are called the TMT steel bars. Therefore, rebar can be identified as one of the most important building materials.

Structural Steel

Structural steels are not only building materials they are used to construct other structures such as bridges, towers, etc. Mostly the structural steels are used to construct part or the whole building. In a reinforced concrete structure, the roof could be constructed from structural steel supports(trusses). In addition, would building could also be constructed from structural steel.

Structural steel includes universal beams (I beam), columns (H column), Rectangular Hollow Sections(RHS), Circular Hollow Sections (CHS), angle sections, etc. Depending on the nature of the structure, application of structural steel as building materials will be applied.

Masonry Materials as Building Construction Materials

Masonry is the most widely used partition material in low-rise building construction materials. Due to the increase in the structure weight, low-weight partition materials are used as replacements to the masonry walls. Mainly, there are two types of masonry that are being used in the building construction

- Brick Masonry

- Block Masonry

Brick Masonry

Bricks are f the eldest building materials used to build structures. Today, there is engineering brick is being used for construction. In addition, there are other different types of bricks that are being used in the construction. Generally, the strength of the brick needs to be 10N/mm2.

Brick masonry walls could be constructed with different thicknesses starting from 113.5mm, 225mm, 300mm, etc. Brick is one of the best construction materials that could protect the structure and maintain comfort. The thermal conductivity is also in the range of the acceptable limit.

Block Masonry

Block is one of the most popular building materials used in modered construction due to the added advantages when compared to brick masonry.

Block are produced with different widths such as 100, 125, 150, 200mm, etc. They even can be produced depending on the requirements in the structure. Not like the brick, block masonry work are very neet. Therefore, the cost of construction is reduced. Plaster thickness, mortar thickness are reduced considerably with block walls construction.

Hollow blocks

Hollow blocks are also produced in the same sizes as solid blocks. The introduction of hollow blocks reduces the weight of the wall significantly. As a result, the overall cost of construction of the structures reduces considerably.

Wood

Wood or the timer is also called under the most useful building materials. Further, there is a tall structure built from timber too. In some of the countries, most of the buildings are constructed from timber. Therefore, time is a very important building material.

Even in the concrete reinforced concrete structure, time is being used for the doors, windows, roof, furniture, etc. most widely. Therefore, time or wood is inevitable building construction material in the world.

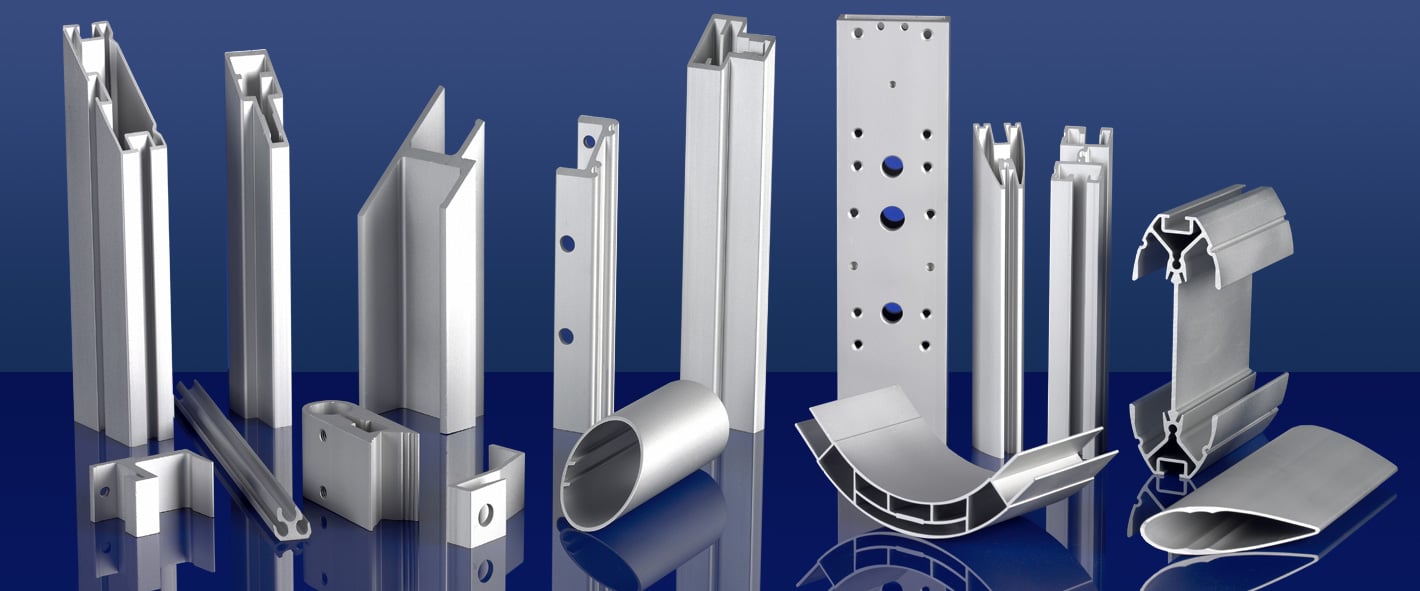

Aluminum

Aluminum is a widely used building material in today’s construction with the increasing demand for the construction and inability to produce materials such as timber. It is eco-friendly material land the effect on the ecosystem is minimal when compared to the use of the timer is considered.

Aluminum is not that strong and it has been made by mixing some other alloys such as copper, magnesium, zinc, etc. to improve its strengths. There are different grades of aluminum products that have different strengths. The selection of the material shall be based on the application. Further, the different profiles create with the aluminum enhance its strength in addition to serving the purpose of the profile section.

Aluminum becomes durable, low cost, low maintenance cost, having a good finish material among the other building materials.

Gass

Glass is one of the most popular building materials used in facade construction. In all scale buildings, facades are constructed as a combination of other facade materials such as brick and block wall. However, in high-rise buildings, the facade is mostly constructed from glass.

It has a low weight when compared to brick and blocks walls. In addition, it improves the aesthetic appearance of the building. Glass is available in different thicknesses such as 6, 8, 10, 12, 16, 20mm, etc. Depending on the nature of the structure and as per the applied loads of the glass, the thickness of the glass is selected to comply with relevant design standards.

In addition, the glass will be used for other purposes such as flooring, internal facades, internal other requirements, etc.

Paint

Paint is the final finish of the building. It covers the external and internal surfaces of the buildings and creates a pleasing appearance. Depending on the application there are two types of paints that are suitable for internal purposes and external purposes.

External paints are generally weather seal types. They should be able to bear the heat and maintain their color unchanged for seasonable time. In addition, they shall be able to minimize the penetration of the water into the brick walls. With the project specifications, the number of layers to be applied will be decided. However, generally, there will be two layers minimum.

The better to perform the higher the number of paint coatings. Especially, for external surfaces, the use of a higher number of layers is a must.

Apart from that, steel structures as also applied with paint to protect them. When we do not use galvanizing, we apply paints to protect the steel from corrosion. The article on the comparison of paint and galvanizing could be studied for more information.