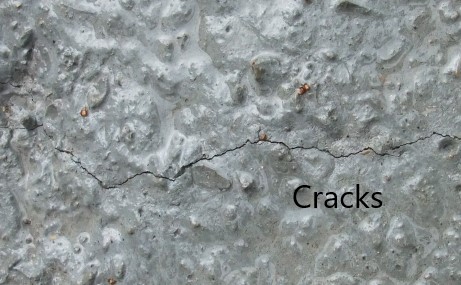

Chemical reactions within the concrete and chemical reactions in the reinforcements lead to cracking of concrete are identified as a chemical attack on concrete. Further, the environmental conditions highly affect the cracking as it provides the necessary ingredients for the reactions.

Chemical reactions create additional tensile stress in the concrete and cause cracking. There are three main causes that could cause cracking due to the actions of the chemical attack on concrete.

- Corrosion of Reinforcements

- Alkali-aggregate reaction

- Cement Carbonation shrinkage

Effect of Corrosion of Reinforcement on Cracking of Concrete

Corrosion of reinforcement could occur in any environment and it is not necessary to be a severe environmental condition. When the basic requirements such as oxygen, moisture and movement of electrons are available reinforcement will crack.

Therefore, it is required to block any of these to avid the combination of them. It is difficult to avoid the movement of the electrons; however, the reinforcement contacting with the moisture and oxygen could be minimized to reduce the corrosion.

By-products of iron oxides and hydroxides are produced as a result of the chemical reactions and they increase the volume within the concrete. The increase of the volume will generate additional stresses on the concrete and when it exceeds the tensile stresses concrete starts cracking.

It is very important to attend these cracks as they will expose the reinforcement to the environment that provides the oxygen and the moisture and subsequently it expedites the corrosion of the reinforcements.

Corrosion of the steel could be when the chlorides are present or due to the carbonation of the concrete. This could happen in the cracked or uncracked concrete. The following figure (from the internet) indicates the damage level that can be expected in each stage due to the chemical attack on concrete.

You may refer to the article “Carbonation Test ” to know more about carbonation and the article ” Concrete Chloride Testing ” or chlorination and its actions. Further, to prevent cracking due to the corrosion of reinforcements, actions shall be taken to avoid reinforcement corrosion. The followings methods could be followed for this purpose.

- Use corrosion inhibitor admixtures

- Use anti-corrosion coating which is not practiced when it comes to a large quantity

- Use water proofings

- Cathodic protection

- Use corrosion protective reinforcement or reinforcement that has the resistance to the corrosion

Effect of Alkali-Aggregate Reaction on Cracking of Concrete

Alkali-aggregate reaction is not common for all structures. This nature chemical attack on concrete occur in certain situations as discussed herein.

Most of the time aggregates are chemically inert. However, some times, they react with the alkali hydroxides in the concrete.

It causes expansion and cracking of the concrete. Na2O and K2O alkali are present in the cement react with active silica in the aggregate. The following factors help the alkali-silica reaction.

- Reactivity of the aggregate

- Alkali content in the cement

- Continuous availability of moisture

- Temperature conditions

What happens in Alkali-Aggregate Rection

- Soluble alkali in the cement dissolves in mixing water and it forms a caustic liquid

- Liquid react with the reactive aggregate in the and forms an expansive alkali-silica gel

- Continuously availability of water and correct temperature, reaction continue to form the silica gel resulting in increasing volume

- With the reaction, separation of the aggregate(debonding) could occur.

- Since the silica gel is confined with the paste, its continuous growth increase the internal hydraulic pressure

- It causes a pattern of cracking

- Cracking will reduce the strength of the concrete

- The formation of the cracks accelerates the deterioration process like carbonation.

The following figure indicates the typical crack pattern that could be observed due to the alkali-aggregate reaction.

There are different methods adopted in the construction industry to minimize or control the alkali-silica reaction.

- Avoid the use of reactive aggregates

- Use low alkali cement having alkali in the range of 0.4%-0.6%.

- Control continues the availability of water

- Control optimum temperature

- Add fine reactive silica in finely powdered form to the concrete mix. It will result in forming calcium-alkali-silicate which is not nonexpanding

Cement Carbonation Shrinkage as Chemical Attack on Concrete

Carbonation shrinkage occurs when the hardened concrete exposed to the air containing carbon dioxide.

Harden concrete reacts with the carbon dioxide with the concrete in the presence of the water.

Calcium Hydroxide converted into the Calcium Carbonate and other components in the cement are decomposed. This process is possible even with the low carbon environment also.

In this process weight of concrete is increasing and concrete subjected to irreversible carbonation shrinkage. During the carbonation shrinkage, calcium hydroxide crystals dissolve and the place is taken by calcium carbonate.

The volume of the calcium carbonate (replaces material) is less than the volume of calcium hydroxide (previous material) and as a result, shrinkage occurs. It could lead to cracking of concrete.

In addition, there is an added advantage of carbonation as it increases the strength of the concrete and increases permeability.