The compressive strength of the concrete and concrete testing is must known information in structural design. Compressive strength is initially checked by doing mix design to make sure the grade of concrete considered in the structural design is achieved. Concrete cube testing or cylinder testing is done to check the development of the strength of the concrete.

In other words, we test the concrete to check whether it has reached or developed beyond the characteristic strength of concrete assume in the design.

Based on the test results, conformity can be checked as per the relevant standards. In this article, we discuss methods provided in BS 5328 and BS EN 206-1. The following areas are covered in this article.

- Rates of Sampling of Concrete

- Method of Casting of Concrete Cubs/Cylinders

- Testing of Concrete Cubs and Cylinders

- Conformity Criteria as per BS 5328

- Conformity Criteria as per BS EN 206-1

Rate of Sampling of Concrete

The rate of the sampling depends on the quantity of the concrete to be poured in a particular concrete. For smaller concrete, the sampling rate is higher compared with large volume concrete.

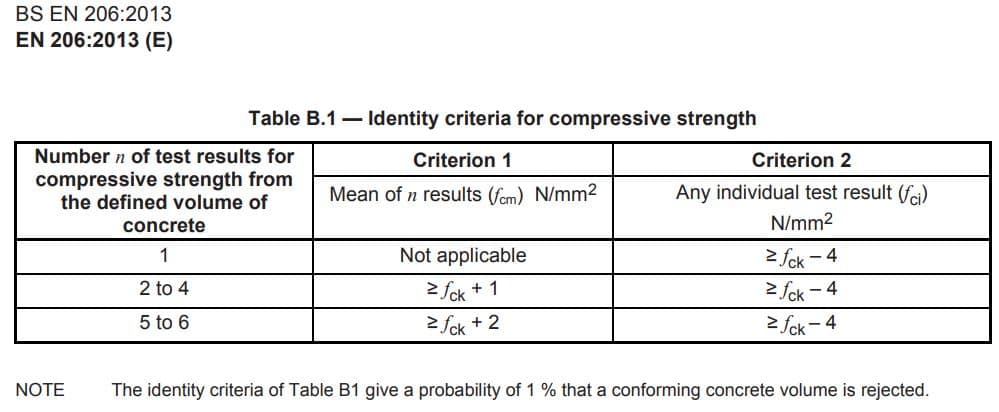

The following table extracted from BS 5328: Part 1 indicates the rates to be considered in the sampling of concrete.

Usually, the volume of the concrete depends on the types of elements to be concreted. Therefore, the above method could be used for all types of elements.

There are two types of casting of testing samples.

- Sample with two cubes/cylinders

- Sample with three cubes/cylinder.

Both the method is common in the construction. However, in large constructions, mostly the two-cube method can be observed.

Method of Casting Cubes/Cylinders

Let’s look at the dimension of concrete testing cubes and cylinders

- Cube – 150mm x 150mm x 150mm

- Cylinder – 150mm diameter and 300mm tall

The following procedure can be used to cast the test samples

- Collect random samples. The collection could be done based on the slump test results and based on the random method. For example, if the rate of sampling is 20m3 and each track carrying 5m3, there will be four tracks. Out of these four tracks, the engineer can select samples randomly if there is no doubt.

- Pour concrete into the cubes in 3 layers.

- Each layer shall be compacted with 35Nos. of blows.

- Finish the top surface by troweling after compaction.

- After 24 hours, remove the specimen from the mould with much care without damaging the sample.

- Necessary identification number or notation shall be marked on the cube for reference.

- Sample shall be submerged in clean water until they are taken for testing. This the standard curing method followed in the testing of concrete.

- Depending on the number of specimens cast for a sample, testing can be done after 7 days and 28 days.

- If there is rapid hardening concrete where it is required early gain of strengths, testing could be done earlier than 7 days depending on the project.

- In addition, there are low strength gain concretes which are tested in 28days and 56days. Those testing shall be done as per the particular project specification.

Effect of Duration of Water Curing on Compressive Strength of Concrete

There is a significant impact of water curing and time of curing in achieving the strength of the concrete. In addition, curing affects the durability of concrete.

The effect of moist curing can be expressed as follows.

- Allowing concrete to dry out immediately achieve only 40% of the strength

- Three days curing increase the strength only to 60%

- 7 days curing increases the strength to 75%

- 28 days water curing increases the strength to 95%.

These facts have shown the importance of keeping the concrete moist to achieve the required strength.

More importantly, testing cubes are kept under the water until they are testing. Therefore, they get maximum curing. However, during the construction concrete not cured mostly the dates specified above. Therefore, the expected strength could not be developed in the actual condition within 28 days.

Further, there are certain risks when the test cubs achieve the required strength marginally as at the site it could not have developed due to the lack of curing. Therefore, due care shall be made when checking the test cube results.

Concrete Testing – Cubes and Cylinders

As discussed above, the time frame for the testing will vary project to project though generally they are tested in 7 days and 28 days. Concrete testing is done to make sure that the assumed characteristic strength during the design.

What is compressive strength?

The strength of the concrete under a compression load. The pressure in terms of stress is measured to find the compression stress that the concrete can bear.

Why compressive strength is important?

Compressive strength is the parameter that represents the concrete in the structural design. Mainly, there are two materials such as concrete and steel in the mix. Therefore, knowing the compressive strength is uttermost important for the designer.

Factors affecting the Compressive strength of concrete

There are many factors that affect the strength of concrete. Out of which seven of them are listed below.

- Quality of the materials such as cement, coarse aggregate, fine aggregate, and water

- Water Cement ration

- Air entrainment

- Aggregate proposition (Coarse: Fine)

- The ratio of Aggregate to Cement

- Use of Admixtures

- Curing period

- Time after concreting

Testing Procedure for Compressive Strength

- Make sure the test cube or cylinder is dry

- Measure the weight of the specimen

- Place the specimen in the bearing plates of the machine as shown in the following figure

- Align properly on the plate with the axis of loading. Maintain the accuracy of ±1% from the size of the specimen between the center axis of the specimen and the lower plate.

- Gradually increase the load until it fails. The rate of loading is 0.6 ± 0.2 N/mm2/s

- Record the maximum force from the machine

The same procedure is followed in the testing of concrete cylinders also.

Compressive strength can be calculated from the following equation

Compressive Strength = Applied Maximum Load / Top surface area of the specimen

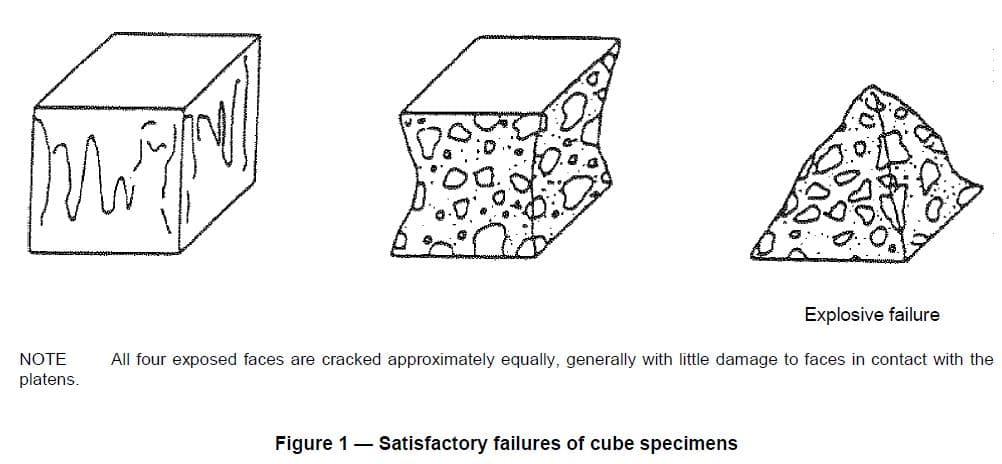

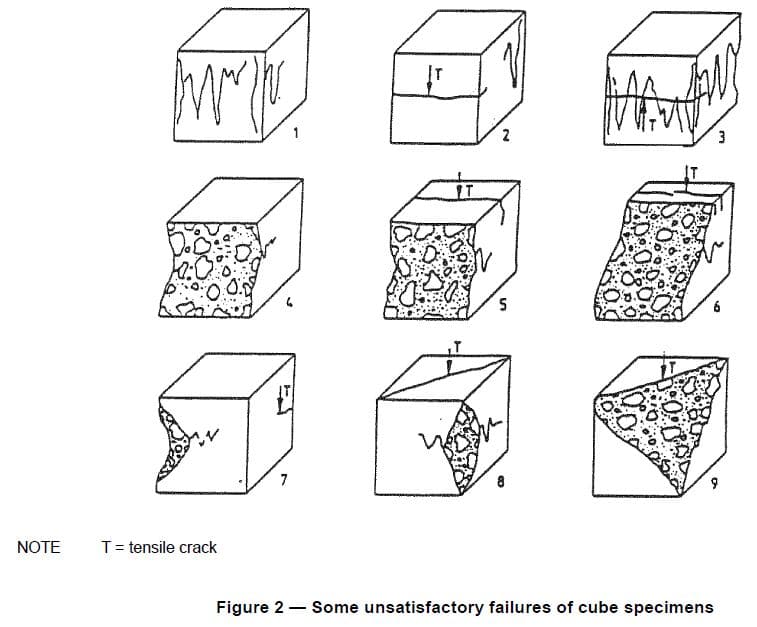

Failure Method

The failure method of the cub or cylinder is taken into account when the results are given. If the cube or the cylinder is failed unsatisfactory, the test specimen is disregarded.

The following criteria given in the BS EN 12309-3 can be used to identify the satisfactory/unsatisfactory failure modes.

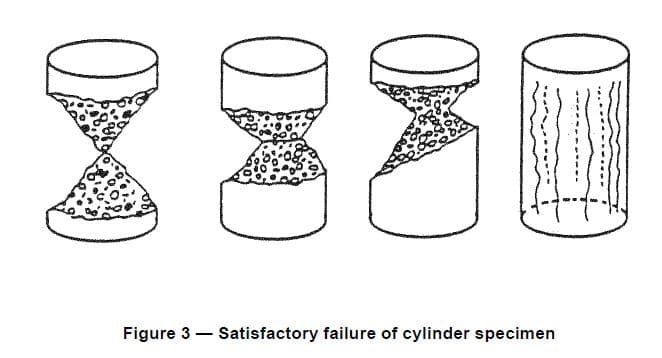

Satisfactory Failure of Concrete

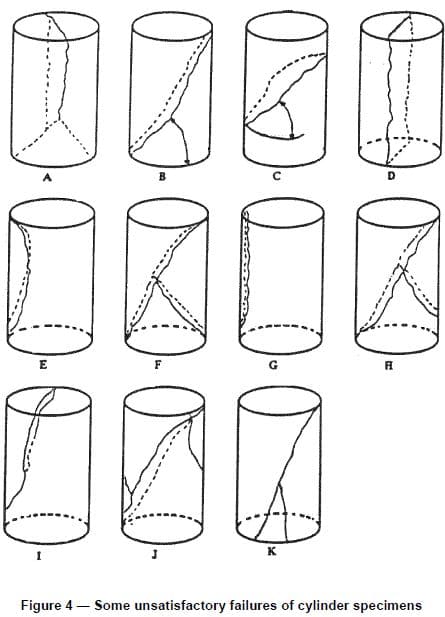

Unsatisfactory Failures of Cube Specimens

Satisfactory Failures of Cylinder Specimens

Unsatisfactory Failure of Cylinder Specimens

It is very important to examine the failure method after testing and before considering the strength of the specimen as a result.

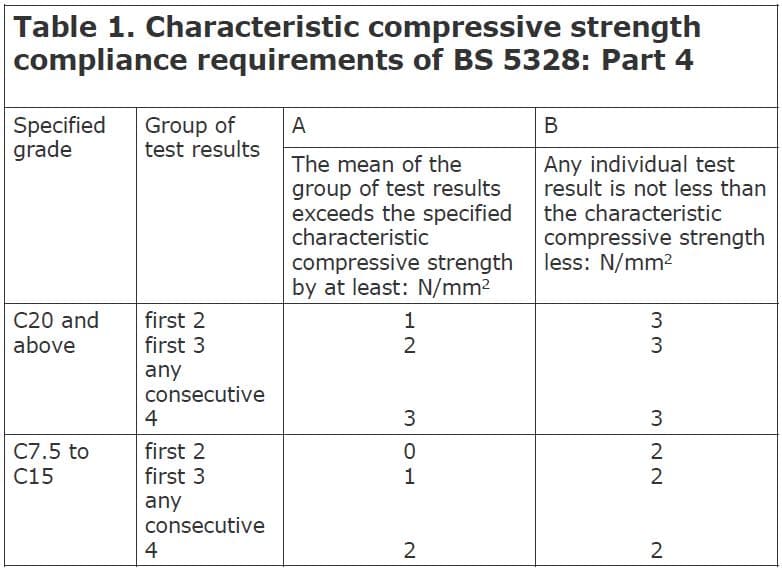

Conformity Criteria as per BS 5328 Part 4 for Compressive Strength

The following information is tabulated as per the information of the BS 5328 Part 4.

The above conformity criteria can be further explained as follows.

Consider cube strength fcu is as C35 and three consecutive test results are available.

Criteria B

fcui ≥ fcu – 3

Example;

fcui ≥ 35-3 = 32 N/mm2

Criteria A for 3 consecutive test resutls

fcum3 ≥ fcu + 2

Example;

fcum3 ≥ 35 + 2 = 37 N/mm2

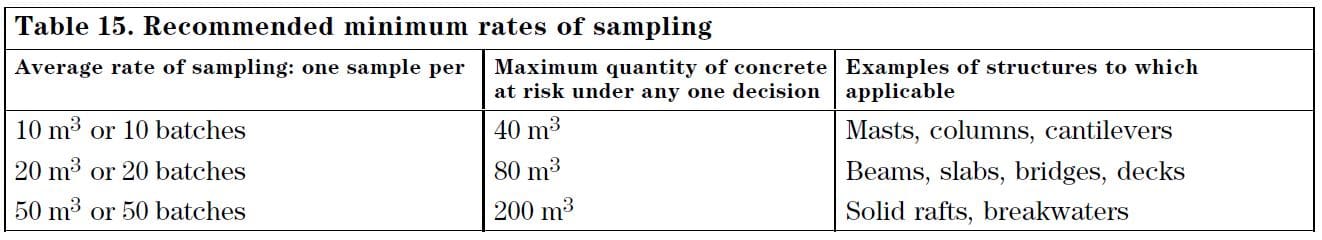

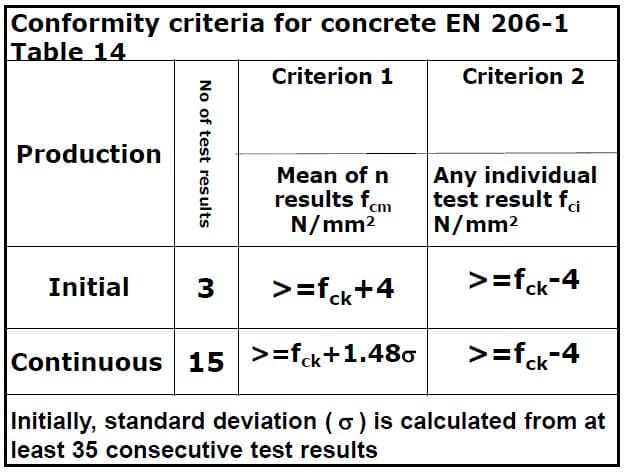

Conformity Criteria as per BS EN 206-1 : 2000

The following compliance criteria is given.

The above criteria can be explained as follows.

Initial production

Consider concrete is as C28/35

Individual Criteria

fci ≥ fck -4

Example

fci ≥ 35 – 4 = 31 N/mm2

Mean of 3 consecutive test results

fcm3 ≥ fck + 4

Example

fcm3 ≥ 35 + 4 = 39 N/mm2

Conformity Criteria as per BS EN 206: 2013

The following guideline is given for conformity criteria.