Temperature control of concrete structures is a crucial part of the construction process. To ensure the quality of a structure, it is important to ensure that the concrete temperature is maintained at the ideal range.

In this article, we will discuss concrete temperature targeting, its importance, and the methods to achieve target temperature ranges. Additionally, guidance and best practices will be shared to support civil engineers in achieving optimum temperature control for concrete structures.

The ideal concrete temperature range before concrete pouring is between 27-35 degrees Celsius. This range allows for the hydration process to occur properly, which is essential for the strength and durability of the concrete. If the concrete mixture is too cold, hydration will be slowed down and can result in poorer quality concrete. If the concrete mixture is too hot, hydration will occur too quickly and can cause the concrete to crack or develop other defects.

There are many factors that can affect the temperature during mixing. The air temperature, the temperature of the ingredients, and the weather are all important considerations. To maintain the ideal range, it is important to take these factors into account and make adjustments to the mixing process as needed.

What Cause Concrete Temperature Rise

The temperature of the concrete is an indication of the heat generated in the cement hydration process. The reaction generates heat.

The main component that contributes to the rise of the temptation of concrete is the C3A. Other ingredients in cement such as C3S, C4AF, and C2S impact in descending order to heat of hydration.

This also can be expressed in a different manner too.

An increase in the cement content and a decrease in the water-cement ratio would also increase the rise of the temperature. In addition, high environmental temperature, high temperature in the aggregates, water, etc. also cause the temperature rise.

Why We Need to Limit the Temperature Rise and Rise Temperature at Cold Weather

There are many consequences of the temperature rise of concrete. Some of the important aspects are as follows.

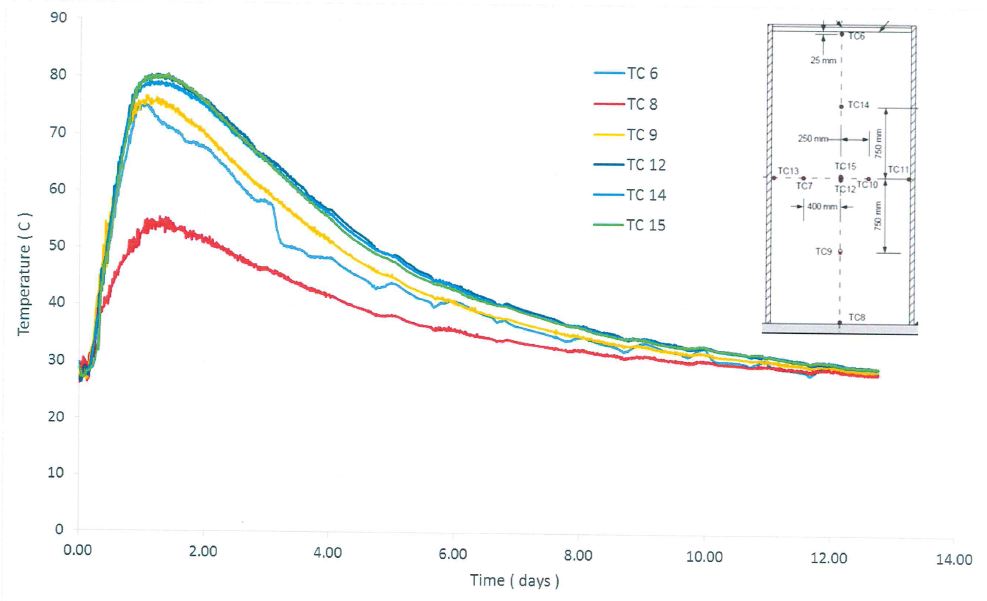

- One of the main causes of the rise of the temperature is the delayed ettringite formation. This occurs with the rise of the concrete temperature. As a general now, the rise of temperature during the hydration process is limited to 700C. Ettringite expands with time and as a result the internal volume of the concrete increase resulting in concrete cracks. It would affect the structural capacity and durability of concrete. Therefore, we need to control the concrete placing temperature.

- Rise in the temperature would increase the surface evaporation leading to quick shrinkage. This would cause concrete surface cracks.

- Rise in the core temperature significantly won’t allow us to maintain the temperature gradient (200C) and temperature difference (250C) between the core and surface within the acceptable range. It would cause the cracking of concrete.

- Adequate Temperature is very important to complete the hydration process. Low temperatures in cold weather could cause incomplete hydration reaction leading to the low compressive strength of concrete. This can be overcome by the concrete curing methods which can be used to increase the temperature.

How to Control Concrete Temperature Rise

As discussed above, it is very important to maintain the temperature as specified in the project specification or relevant code of practice. The followings are some of the methods that could be adopted during the construction to keep the maximum temperature within the limits.

- Use of Low heat cement

- Reduce the temperature of the aggregates. Water cooling can be done.

- Use of chilled water for concrete mixing

- Reduce the cement content but this may not be always possible when we need high concrete compressive strength.

- Use cement replacement such as fly ash to control the cement content. We may replace the cement content by about 25-35%.

- Use curing methods like internal colling. Pipes could be laid within the concrete for the circulation of water. After concrete pouring water can be circulated while monitoring the temperature of concrete.

- Avoid daytime for concreting.