TESTING OF CONCRETE AN OVERVIEW

Concrete testing is done to achieve the quality of concrete work. There are different types of test that are done in fresh concrete and harden concrete.

Slump test, flow test, temperature checks are usually done in fresh concrete while concrete cub test or concrete cylinder test is mainly done in hardened concrete.

It is prime important to make sure the poured concrete is as per the approved mix design at the beginning of the project. Thus, as per the project requirements, concrete is tested before placing.

Sump of the concrete is decided as per the mix design which is done according to the project specification which follows the relevant standards. Following procedure is followed when sump of the concrete is tested.

Concrete Slump Test

- Clean the internal surface of the mould and apply the oil

- Place the mould on the smooth horizontal surface (usually, steel plate is used)

- Fill the concrete in three layers

- Each layer shall be compact with 25 stokes

- Remove excess concrete and level the top surface

- Clean outside of the mould for excess concrete

- Remove the mould from the concrete slowly

- Measure the height between the mould and top level of the concrete.

- This measurement is identified as the slump of the concrete

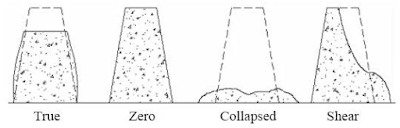

There are different types of slumps based on the deformation of the concrete after the mould is lifted. True sump, zero slump, collapse slump and shear slump are mainly identified as a main different type of slumps.

True slump is the only slump that the measures are taken for monitoring the workability of the concrete. Zero slump is usually un-deformed concrete which does not have movement in the concrete with the lifting of the mould.

This could be mainly due to the low water-cement ratio or due to the hardening of the concrete at the time of the testing. Collapse sump of the concrete is mainly due to the high water-cement ratio.

These type of concrete could be retested for slump again. If sump values are not achieved, concrete will not be allowed to place. Concrete will be retested if shear slump was observed. Different type of slump can be indicated as the following figure.

Following table indicate some of the guidelines that could be used for testings of concrete and its related materials.

| Designation | Title of the Standards/ Code of Practices |

| BS 12 | Specification of Portland Cement |

| BS 812 Part 2 – 1975, | Methods of testing of aggregates |

| BS 882 – 1992 (BS EN 12, 620:2002) | Specification for aggregates from natural sources for concrete |

| BS 1881 -1998 | Methods for testing of concrete |

| BS 3148- 1980 | Method of testing water for making concrete |

| BS 4449-2005 | Specification for carbon steel bars for the reinforcement of concrete |

| BS 8666:2005 | Specification for scheduling, dimensioning, bending and cutting steel reinforcement for concrete |

| BS 5075, Part 3 – 1985, Part 1-2:1982 | Concrete admixtures |

| BS 8500-1-2002 | Method of specifying concrete mixtures |

| BS EN 197-1:2000 | Specification for Portland pulverised- fuel ash cement |

| BS 8110, Part 1:1997, Part 2,3 :1985 | Structural Use of concrete |

| ASTM C 40-2004 | Organic impurities in fine aggregates for concrete |