Control joints in concrete are very important especially in the construction of on-grade slabs which rest on the ground.

Different stresses induced in the slab lead to cracking of the slab and as a result the finishes such as tiles get damaged.

Therefore, it is very important to have control joints in the slab in a controlled manner. If we do not provide adequate joints and construct them correctly, the rectification cost would be much higher than the initial cost incurred for the construction of control joints.

What are control joints in concrete ?

Joints created other than the expansion and movement joints in slabs. They are a kind of joint that does not allow the movement of the expansion joint.

But they allow some movement to relieve the internal stresses.

The control joints are also called contraction joints.

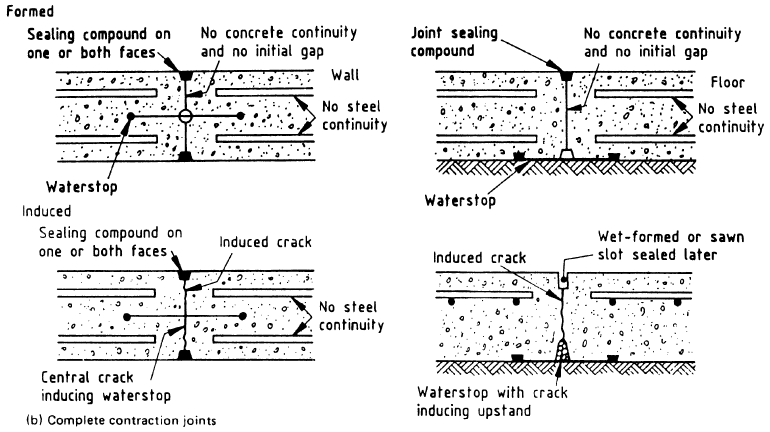

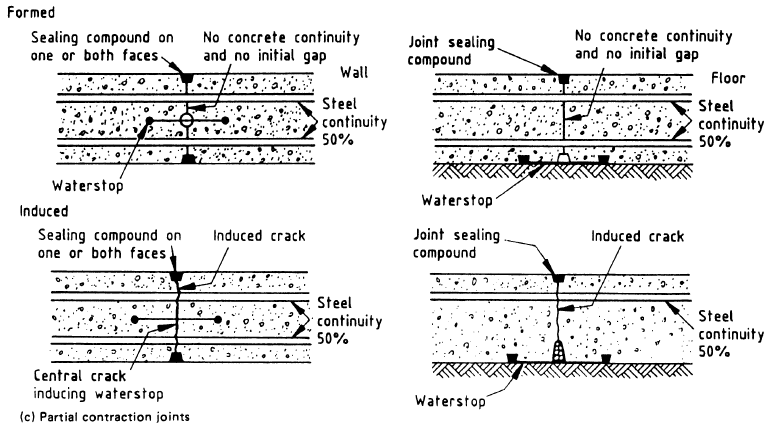

The following type of control joints can be identified as per BS 8007.

- Complete Contraction Joints

- Partial Contraction Joints

In addition, the formation of the contraction joint is also different from each other.

- Formed Control Joints

The control joint is formed initially and let behave as required for the structure.

- Induced Control Joints

Initially, there is no separation in the concrete. The groves(slots) created at the top and bottom of the slab creates leads a formation of cracks.

There are different types of control joints as stipulated in the BS 8007. The following figure indicates different control joint arrangements.

Why do we need Control Joints in Concrete?

Control joints are used to control cracking in the concrete.

There will be additional stress in the concrete placed on the ground or on the top of the concrete layer as second-stage concrete due to the following reasons.

- Movements caused due to the shrinkage of the concrete during curing of concrete

- Small expansion and contractions movements caused by absorption and expulsion of moisture in concrete

If we do not provide an adequate allowance to relieve the stresses developed due to the movement of concrete, there will be cracks in the concrete.

The crack pattern would be irregular and random. There may be spider pattern cracks also. The formation of the cracks or the pattern of the cracks depends on the restrains developed internally and by boundaries.

At this point, let’s discuss the main difference between the control joint in concrete and expansion joints.

What is the difference between Control Joint and Expansion Joint

A control joint is a kind of joint that does not allow physical movement in the concrete but allows to release of the additional stress developed in the concrete.

Other hand, the expansion joint allows the movement and release the internal stress.

Both the control joint and expansion joint have different functions.

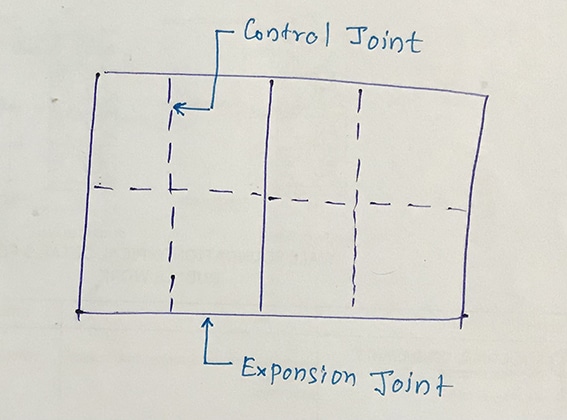

However, in general, in on-grade slab construction, we use a combination of control joints and expansion joints. We construct control joints in concrete within an area covered by expansion joints. We do not need to construct expansion joints as control joints.

While the expansion joint release the stress, the control joint can relieve the stress at the intermediate level.

As indicated in the above figure and based on the floor arrangement, a joint pattern shall be finalized. Thus, we can decide whether we need an expansion joint or not. For a smaller area, the internal stresses can be relieved by control joints.

How to Create a Control Joint

The following procedure can be used to construct a joint pattern.

- As indicated in the initial figures, the joint can be created during the construction or we can let it form with the development of the stresses.

- Formed joints have no connection at the joint other than continuation or discontinuation of reinforcement as required.

- The induced joint will be developed by cracking the slab with the internal stresses.

- It is required to create a slot to form internal cracks. The depth of the slot is generally one-fourth of the slab thickness.

Advantages of Control Joints over Expansion Joints

- Expansion joints are more costly when compare to the control joints.

- Control joints can even be created after the construction of the slab.

- The Joint is more efficient than the expansion joint.

- Even smaller width is adequate for control joint and it can be ket without filling flexible material when it is thinner. However, there is a possibility of filling the gap with foreign materials.

- Expansion joints, we need to do joint sealant and need attention on the edges as there are possibilities in damaging if there are vehicular movements.

Spacing of Contraction Joints

The spacing of the contraction joint or the control joints in concrete depends on many factors as shown below.

- The thickness of the slab

- Water content in the concrete

- Rater of evaporation

- Humidity

- Availability of reinforcement net

- Temperature

- Dimensions of the slab

- Restrains provided by the ground or resting base

- The geometry of the slab

And many more factors could affect the spacing of the control joints.

Unreinforced slab

- ContractionJoint spacing could be maintained in the range of 4-5m. However, based on the other factors, the spacing could be reduced to around 3m.

Reinforced Slab

- The joint spacing could be maintained in the range of 12-25 m.