Cracking of concrete is unavoidable it is not considered during the design and construction. Environmental factors, structural form and construction procedures highly affect the cracking of concrete. This article is concentrated on type of concrete cracks and their formation.

There are three stages that which the cracking of concrete can be observed.

- Cracking of immature concrete ( before hardening)

- Cracking of hardened concrete

- Construction practices

Different factors affecting the cracking under each category are discussed in this article. It is very important to know the environmental conditions, structural loadings, special structural arrangements, special restraints, material properties, etc. at the design stage and the construction stage to minimize the cracking of concrete which is unavoidable if not attended to seriously.

Cracking of Immature Concrete

Immature concrete is usually known as plastic concrete is the unhardened concrete or concreting getting hardened. There are different reasons for cracking concrete during it gets hard. Evaporation of moisture from concrete, construction movement, etc affects the concrete to crack. These types of concrete cracks in immature concrete can be discussed under two main categories.

- Plastic cracking

- Constructional movements

Plastic Cracking

Cracking that causes the plastic stage of the concrete is known as plastic stage cracking. Cracking is caused due to two main reasons.

- Plastic Shrinkage

- Plastic Settlement

Plastic Shrinkage Cracks

Plastic shrinkage cracks occur in the concrete surface when the moisture in the concrete surface evaporates at a rate greater than it supplies by the bleeding. Concrete surface drying with the evaporation and it shrinks resulting in cracks in the concrete surface. It is very difficult to control the cracking of the concrete by modifying the concrete mix to achieve the desired rate of bleeding. However, plastic shrinkage cracking can be minimized by taking different actions as mentioned below.

- As the rate of evaporation is affecting the cracking, it could be controlled by different means. Provide windbreaks to reduce the wind speed and sunshades could be provided to reduce the heat in the concrete surface to reduce evaporation.

- Sprays can be used to reduce evaporation.

- The temperature of the concrete could be reduced at the time of placing.

- Place the concrete when the environmental temperature is low. Starting concrete placing evening or at night will reduce the cracking of concrete.

- Finish the concrete surface quickly and when it is possible, place the wet gunny bags, polythene to cover the surface, etc.

- Start curing as soon as possible. Membrane-type curing could also be done.

- If applicable, accelerators could be used to reduce the setting time of the concrete.

Plastic Settlement Cracks

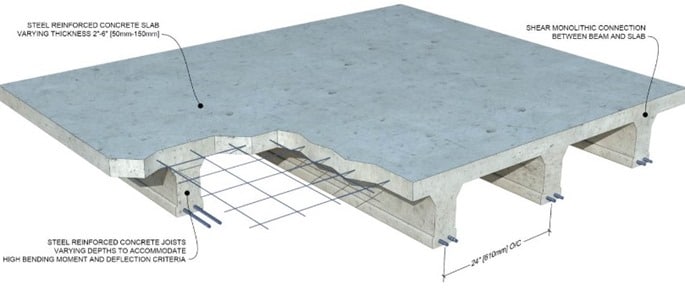

Plastic settlement cracks occur in unhardened concrete when the settlement of the fresh concrete is obstructed by the reinforcement or formwork. These types of concrete cracks occur within a few hours of concreting. In fresh concrete, dense material tries to move downward and water comes up. This process is blocked by top reinforcement bars or formwork, and as a result, plastic shrinkage cracks could appear. The following figure indicates how it cracks.

These cracks can be observed along the reinforcement lines as we can see in the above figure and the following actions can be taken to minimize cracking at the mix design and construction stage.

- Mix designs having lower bleeding characteristics could be used.

- Increase the cover-to-bar diameter ratio

- When concrete is poured into the floor, it could be done on a wet based as it avoids loss of water from the concrete

- Avoid any movement of the formwork by fixing them firmly

- Compact the concrete adequately

- Concreting of deeper sections could be done early for allowing them to settle and to match the settlement with other pours.

- Start curing as early as possible and do it adequately

Cracking of Constructional Movement

The effect of the movement of the formwork or the concrete supports could lead to the cracking of concrete. This issue is more common in low-rise buildings as the skills and attention of the contractors are comparatively less when compared with high-rise buildings. There are two main types of movements

- Movement of formwork

- Movement of sub-grade

Lack of attention to the formwork of the ground condition when concrete pours into the ground causes the cracking. It is also the responsibility of the consultant to make sure the conditions of the support are acceptable to proceed with the concrete. Formwork shall be checked before the concreting and during the concreting for knowing whether there is a risk of movement of formworks.

Ground conditions shall be checked and should be verified with the necessary test to know it can bear the load of the concrete without movements affecting the concrete hardening. Concrete has a much higher density and therefore, it exerts a very high weight. For example, in a filled ground, compaction tests could be done to make sure the concrete has adequate strength.

Cracking of Hardened Concrete

Matured concrete or hardened concrete also cracks due to loading, thermal effects, accidental effects, etc. Some types of cracks can be controlled through the design by considering them when the design is done. For example, the cracking of concrete due to the delayed ettringite formation can be minimized by reducing the rise of core temperature, which will be further discussed in the latter part of this article. However, it is very difficult to attend to all the factors during the design phase and also some of the long-term chemical effects like alkali-silica reactions are very difficult to control. The cracking of the hardened concrete can be discussed under four main categories.

- Physical (shrinkable aggregates, drying shrinkage and Crazing)

- Chemical(corrosion, alkali-silica reaction and cement carbonation shrinkage)

- Thermal(Freeze/thaws cycles, seasonal temperature variations and early thermal contractions)

- Structural (accidental overloads, creep effects and design loads)

Each of the above categories and their influence on cracking under different subject areas is discussed in different articles published on this site Click on them for more information and based on the main causes of cracking the above categorization was made.

Cracking due to the construction practices is also discussed in a different article and it could be referred to for more information

Source: Internet

Related Articles

- Early Thermal Cracking [calculate R/F requirements]

- Effect of Construction Practices on Cracking

- Cracking of Concrete [ basics, types and causes]

- Physical Reasons for Cracking

- Fundamental of Cracking of Immature Concrete

- Foundation Cracks types why they serious

- Cracks in Basement Wall [a detailed study]

- What is Spalling of Concrete – causes and repair

- 20 Factors Affecting Durability of Concrete

- Durability of Concrete [Requirements and Problems]

- Vibration of Concrete [methods and correct procedure]

- 6 Factors Affecting Curing Time of Concrete

- 11 Methods for Curing of Concrete

- A Detailed Study on Concrete[from scratch]

- Types of Shrinkage in Concrete [detailed study]