In the world of concrete engineering, the term “Delayed Ettringite Formation” might not be a household phrase, but it plays a significant role in the structural integrity of concrete structures.

This article will delve into the intricacies of Delayed Ettringite Formation (DEF), exploring its causes, effects, preventive measures, and the chemical reactions behind it. Let’s discuss the mystery behind this phenomenon.

What is Delayed Ettringite Formation?

Delayed Ettringite Formation, commonly abbreviated as DEF, is a chemical reaction that occurs in hardened concrete. It involves the formation of ettringite, a mineral compound consisting of sulfate, aluminate, and water, within the concrete matrix.

Unlike other types of ettringite formation, DEF occurs at a delayed stage, long after the concrete has set and hardened.

Mostly the DEF can be observed in the concrete core and the rise of the concrete core temperature is the main consern.

Why does DEF is Formed

Delayed Ettringite Formation (DEF) is a chemical reaction that can occur in concrete, leading to structural damage and reduced durability. It happens when certain conditions are met within the concrete mix. Here are the key factors contributing to the occurrence of DEF:

- High Temperature and Moisture:

DEF typically occurs in concrete that has been exposed to high temperatures (e.g., during curing) and moisture. The combination of these conditions can trigger the DEF reaction.

In construction, usually in thick concrete, concrete core temperatures are maintained at curtail levels to avoid the internal cracking and avoiding the delayed ettringite.

The common practice is to maintain the concrete core temperature at 70 degrees of Celsius in order to the avoid the DEF. Those this is a typical value, this may be increase based on the cement combinations used in the mix design.

- Alkali Content:

A high alkali content in the concrete mix can increase the likelihood of DEF. Alkalis, such as sodium and potassium, can react with certain minerals in the concrete, promoting the formation of ettringite.

- Delayed Cooling:

Rapid cooling of concrete after a high-temperature phase can help prevent DEF. However, if the concrete is not cooled down quickly enough, it provides more time for the DEF reaction to occur.

In larger concretes, there rise of the concrete heat started from first day and it would come to peak in 2-4 days. During this period, curing methods which used to extract concrete heat may be used.

One such method is placing the pipes inside the concrete and circulate the water. This curing methods is more useful in maintain the concrete temperature acceptable level.

- Sulfate Sources:

DEF is related to the presence of sulfates, which can come from various sources. External sources of sulfates, such as groundwater or soil, can infiltrate the concrete and contribute to DEF. Additionally, sulfates can be present in the cement used in the concrete mix.

- Aluminum Content:

The aluminum content in the concrete can also influence DEF. Higher aluminum content can lead to the formation of ettringite, especially when it reacts with the sulfate ions present.

- Curing Conditions:

Improper curing practices, such as letting the rise of the concrete temperature unnecessarily would cause the issues.

Therefore, as mentioned previously as well the rises of the concrete core temperature would be controlled by an acceptable method.

Carrying out mockup test is one method to identify the core temperature, temperature gradient and temperature difference between the core and surface.

If we know these values, necessary modifications to the mix design and curing method can be done.

- Mix Design:

The specific mix design of the concrete, including the type and proportions of materials used, can influence the potential for DEF. Some concrete mixes are more susceptible to DEF than others.

As discussed under the curing of concrete, carrying out a trial to know the behavior of the concrete would enable to modify the concrete mix to reduce the rise in the concrete temperature.

- Age of Concrete:

DEF typically occurs within the first few months to a couple of years after concrete placement. It is a delayed reaction and often becomes noticeable as cracking and expansion within the concrete.

To mitigate the risk of Delayed Ettringite Formation, it’s crucial to carefully control the mix design, curing conditions, and the environment in which the concrete is placed. Additionally, using sulfate-resistant cements and taking measures to minimize the ingress of external sulfates can help prevent DEF in concrete structures.

Understanding the Chemical Reactions in DEF

The chemical reactions that drive Delayed Ettringite Formation are intricate and play a pivotal role in its development. The primary reactions involved include:

1. Sulfate Attack on Aluminate Compounds

The initial step in DEF involves the attack of sulfate ions (SO4²⁻) on aluminate compounds in the cement matrix. In Portland cement, one of the primary sources of aluminate is tricalcium aluminate (Ca₃Al₂O₆). When sulfate ions come into contact with tricalcium aluminate, the following reaction takes place:

3Ca₃Al₂O₆ + 3CaSO₄ + 32H₂O → 3Ca₃Al₂(SO₄)₃·32H₂O

In this equation, Ca₃Al₂O₆ represents the aluminate compounds, and CaSO₄ represents the sulfate ions. This reaction generates calcium sulfoaluminate hydrate, a precursor to ettringite.

2. Formation of Ettringite

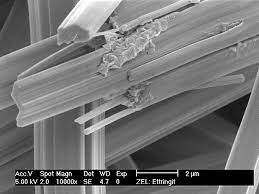

Once sulfate ions react with aluminate compounds, ettringite begins to form. Ettringite has a characteristic needle-like crystal structure and is a primary component of DEF. The chemical equation for this reaction is:

3Ca₃Al₂(SO₄)₃·32H₂O + 2Ca₃Si₃O₉ → 3Ca₆Al₂(SO₄)₃(OH)₁₂·26H₂O

In this equation, the calcium sulfoaluminate hydrate from the previous reaction combines with calcium silicate hydrate, another common component of cement, to produce ettringite.

This formation of ettringite crystals is what contributes to the expansion and cracking observed in DEF-affected concrete.

3. Delayed Reaction

As the name suggests, the formation of ettringite in DEF is delayed. This delay occurs because the reaction requires time to reach completion.

Initially, the concrete appears sound, but ettringite crystals gradually grow and exert pressure on the surrounding structure. The delay can range from weeks to months, making DEF a challenging issue to detect and address.

Understanding these chemical reactions is essential for concrete engineers and builders because it allows them to develop strategies to prevent or mitigate DEF in their projects.

Effects of Delayed Ettringite Formation

Understanding the effects of Delayed Ettringite Formation (DEF) is vital, as it can have a substantial impact on concrete structures:

1. Compromised Structural Integrity

DEF can significantly reduce the compressive strength of concrete. The formation of expansive ettringite crystals weakens the material, potentially leading to structural failure.

This effect is especially concerning in critical infrastructure like bridges and high-rise buildings.

2. Cracking and Expansion

One of the most noticeable consequences of DEF is the development of cracks and expansion within the concrete.

The growth of ettringite crystals exerts pressure on the surrounding matrix, causing visible damage. These cracks not only diminish the aesthetic appeal of structures but also compromise their durability.

3. Long-Term Durability Challenges

Concrete structures affected by DEF often face long-term durability issues.

The presence of expansive ettringite crystals can accelerate concrete deterioration, increasing maintenance costs and reducing the service life of the structure. This poses a significant concern in terms of sustainability and cost-effectiveness.

How to Identify DEF

Identifying Delayed Ettringite Formation (DEF) in concrete structures is important for assessing potential structural damage and taking corrective actions. Here are some common methods and signs to identify DEF:

- Visual Inspection: Perform a visual examination of the concrete surface. Look for the following signs:

- Cracking: DEF often results in distinctive map-like cracks on the concrete surface. These cracks may radiate from a central point or follow a polygonal pattern.

- Expansion: DEF can cause the affected areas of the concrete to swell or expand. This can result in noticeable deformations or bulging in the concrete surface.

- Discoloration: In some cases, the concrete may exhibit discoloration or a whitish, powdery residue on the surface, which can be a sign of ettringite formation.

- Petrographic Analysis: Petrographic analysis involves examining thin sections of concrete samples under a microscope. A petrographer can identify the presence of ettringite crystals, which have a characteristic needle-like appearance, within the concrete matrix.

- Chemical Testing: Chemical testing of concrete core samples can be performed to determine the composition of the concrete and the presence of ettringite. Laboratory tests, such as X-ray diffraction (XRD) and scanning electron microscopy (SEM), can help confirm the formation of ettringite.

- Mechanical Testing: DEF can weaken the affected areas of concrete, leading to reduced structural integrity. Conduct mechanical tests, such as compressive strength and modulus of elasticity tests, on core samples from the concrete structure. A significant reduction in strength may indicate the presence of DEF.

- Monitoring and Documentation: If there is suspicion of DEF in a concrete structure, it’s essential to monitor the affected areas over time. Document any changes in crack patterns, expansion, or other visual indicators. Frequent monitoring can help assess the progression of the condition.

- Historical Data: Review historical records, construction documents, and maintenance reports to gather information about the concrete mix design, curing methods, and any potential issues during construction. This information can provide context for the presence of DEF.

- Expert Consultation: In complex cases or when conclusive evidence is needed, consult with structural engineers, materials experts, or petrographers who have experience in diagnosing DEF. They can perform more detailed investigations and recommend appropriate remediation measures if necessary.

It’s important to note that DEF can be a slow-developing condition, and its severity can vary. Early detection and assessment are crucial for determining the appropriate steps to address DEF and prevent further damage to the concrete structure.

Preventive Measures

Taking proactive measures to prevent Delayed Ettringite Formation is essential to ensure the longevity and safety of concrete structures. Here are effective preventive strategies:

- Controlled Concrete Temperature

Maintaining proper concrete curing temperatures is crucial in mitigating DEF. Excessive heat during the early stages of curing can accelerate chemical reactions leading to ettringite formation.

By carefully controlling the curing temperature, engineers can reduce the risk of DEF.

- Low-Alkali Cement Selection

Opt for low-alkali cement when designing concrete mixes. High-alkali content can increase the susceptibility of concrete to DEF.

Using low-alkali cement minimizes the potential for alkali-silica reactions, a common precursor to DEF.

- Thoughtful Aggregate Selection

Select aggregates with low sulfate content to minimize the likelihood of DEF.

Aggregates containing high levels of sulfates can promote sulfate attack on aluminate compounds within the concrete, triggering ettringite formation.

- Monitoring and Testing

Regular monitoring and testing of concrete structures are essential. Periodic assessments can detect early signs of DEF, allowing for timely intervention and repair.

Petrographic examination and non-destructive testing techniques are valuable tools for identifying DEF-related issues.

- Quality Control

Implement stringent quality control measures during the concrete production and construction processes.

Ensuring that materials are of the highest quality and that construction practices are sound can help prevent DEF from occurring in the first place.

By implementing these preventive measures, engineers and builders can significantly reduce the risk of Delayed Ettringite Formation, ensuring that their concrete structures remain resilient and durable throughout their intended lifespan.

Delayed Ettringite Formation is a complex phenomenon driven by intricate chemical reactions. By understanding its causes, effects, and the underlying chemistry, engineers and builders can take proactive steps to ensure the durability and safety of their concrete projects.

FAQs

1. Can DEF be completely prevented?

While complete prevention of DEF is challenging, it can be significantly reduced by implementing proper construction practices and material selection.

2. How is DEF diagnosed in concrete structures?

DEF can be diagnosed through petrographic examination, where concrete samples are analyzed for the presence of ettringite crystals.

3. Are there any alternative materials to mitigate DEF?

Some additives and supplementary cementitious materials can be used to mitigate DEF and improve concrete’s resistance to it.

4. Can DEF be repaired once it occurs?

Repairing DEF-affected concrete involves removing the damaged portions and applying appropriate repair materials to restore structural integrity.

5. What are the long-term implications of DEF on concrete structures?

The long-term implications of DEF include reduced service life, increased maintenance costs, and potential safety hazards, making preventive measures crucial in construction projects.