Driven pile foundations are used in low rise buildings and bridge constructions mainly. When the topsoil is not in good condition and when it does not have the adequate bearing capacity to resist the load from the superstructure, a driven pile is used.

The driven pile is a type of pile that inserted up to the hard layer in the soil where it can provide the required end bearing and skin friction.

Since the cost of construction is less when compared with the cast in situ bored piles, these types of piling work are more popular in bridge construction.

Mainly there are four categories which as based on the nature of the material.

Types of Driven Piles

- Steel Piles

- Precast concrete piles

- Timber Piles

- Composite Piles

Let’s discuss above each of the driven piles separately.

Steel Driven Piles Foundations

There are different types of driven piles constructed from the steel. Since the steel is readily available, construction can be done quite easily.

Further, steel piles such as micro piles can be used to support heavy loads applied from bridges and other types can be used to support medium level loads.

The main issue with the steel driven piles is the corrosion. However, they are placed below the ground level. Therefore, the presence of oxygen for corrosion is minimal.

Let’s discuss available types of steel piles.

Types of Steel Driven Piles

- Micropiles

Micro piles are steel casinos filled with concrete. Further, depending on the applied loads, pile diameter can be increased based on the applied load.

If required, a reinforcement cage can be inserted into the pile to increase the pile load-carrying capacity.

Pile design can be done as guided in the article pile foundations design, construction and testing guide.

- H Piles

Hot rolled sections are used in the construction. They are welded together to increase the length.

These types of piling construction are not widely used in the construction.

However, on special occasions, H piles can be used.

- Steel Box Piles

Four steel sheets welded together to create box shape pile or sheet piles welded together to create a hollow box section can be used in the construction.

The inner core can be filled with concrete to improve the lateral stiffness, bending stiffness, torsional stiffness, etc.

- Screw Piles

Cast iron screw shape piles are driven by rotary drilling and are not that popular type of piles used in the construction.

Depending on the nature of the soil, and as per the purpose of using different diameters could be used in the construction.

- Steel Railed Piles

Old rails have been as steel piles. Three rails are welded at the top or bottom.

Butt- welding is used to join two sections to increase the length of the pile.

Since these piles are from abundant materials, the cost will be less.

Further, it could be considered as green construction as we reuse the materials.

Precast Concrete Driven Pile Foundations

The most widely used type of driven piles in the construction. Mainly there are two types of precast piles.

- Normally reinforced precast piles

- Prestressed Piles

The following key points are highlighted in relation to the precast piles.

- These piles can carry high bending and axial stress.

- Piles constructed with adequate cover and grade of concrete are not subjected to deteriorations.

- Therefore, these piles are more durable.

- However, the composition of concrete, porosity of the aggregates, cover to the reinforcements, etc. could cause deterioration of the piles.

- As a result, durability issues could reduce the lifetime of the piles.

- Use of sound and hard aggregates, proper mix design, proper placing, compacting of concrete, proper curing of concrete, etc improve the durability of concrete.

- The minimum cover could be maintained as 50mm as a durability requirements.

- Further, prestressing reduce the cracking of the concrete.

- Galvanizing the reinforcement is suggested if possible in bearing the cost.

There are no major issues like corrosion of steel in precast pile construction.

Further, it is easy to construct than other type of pile foundations. In addition, time take for completing a single pile is also lesser.

The cost of construction is also comparatively very less compared with the cast in situ bored piles.

Precast piles are available in different dimensions such as 300, 350, 400, 500mm, etc. In addition, they can be obtained in a circular or rectangular shape.

Timber Piles

Let’s see basic things about the timber piles in brief.

- Timber piles can be in different dimensions having different load capacities.

- They are not widely used due to the low load-carrying capacities

- A tree is used as a timber pile after removing the branches

- The bottom diameter would be in the range of 300-500mm

- The top diameter could be in the range of 125 – 250mm

- Generally, piles are available in length range 9000mm – 18000mm

- The pile can bear the applied loads and driving forces. However, it is vulnerable if hard driving is done

- Timber pile are vulnerable to deteriorations

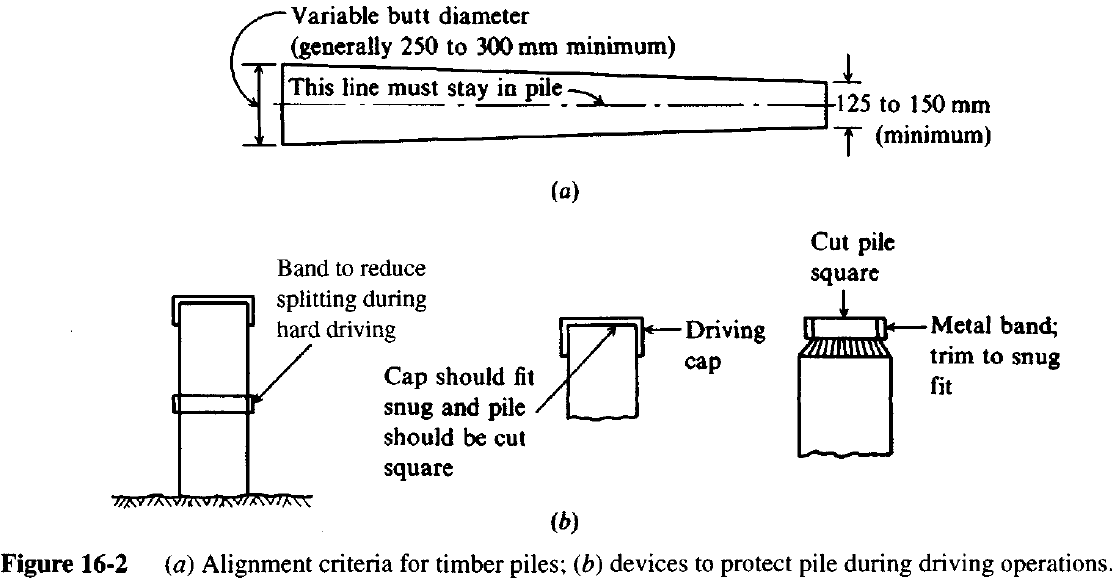

The following figure taken from the book Foundation Analysis and Design by Bowels indicates the necessary arrangements to be made in a driven timber pile.

The design load of the timber piles is in the range of 150kN-250kN. The maximum permissible load is about 300kN. However, testings done have proven that it could bear a maximum load of about 400kN.

Attention shall be made when the pile is driving through hard layers as it could damage the pile.

Composite Piles

Composite piles were started using about 60 years ago. The main purpose of composite piles was to construct relatively longer piles economically.

Different materials are used to construct composite piles. Further, the selection of the material shall be done to suit the conditions. The following combination could be expected.

- Timber pile is embedded below the existing ground level and above the existing ground level (up to top-level) to be constructed from concrete.

- Concrete filled steel pipe or H iron place lower part of the pile and upper section to be constructed from concrete.

- Construct upper section with precast piles

The composite piles are in the range of 18m-36m. However, the length of 54m has also be driven.

The optimum load range about 300kN-800kN and the maximum load limit is about 1500kN.

One of the main disadvantages of the composite piles is creating a proper joint between two materials.

Design Precast Piles (Driven Pile Design)

The design of precast piles needs to address two issues.

- Pile shall be designed to carry the loads from the superstructure

- Piles shall be designed and detailed to carry the impulsive load applying during the driving

The structural design and geotechnical design of driven piles for superstructure loads could be done following the same procedures discussed in the article pile foundations.

Special detailing techniques shall be adopted to pile to carry the forces generated in the pile driving process. There are special details for precast piles.

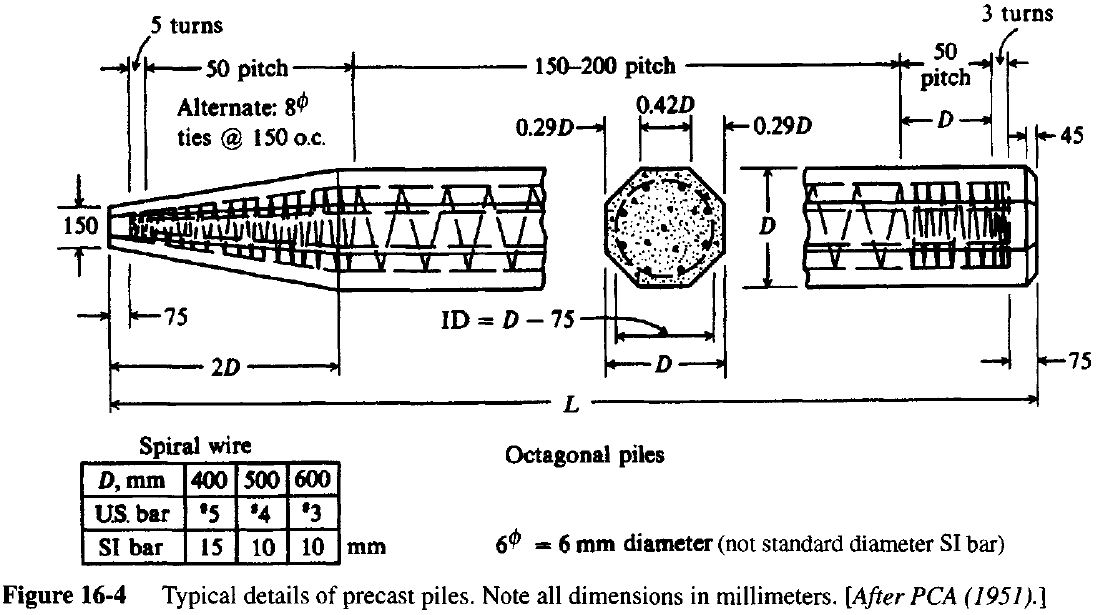

The following figure taken from book Foundation Analysis and Design by Bowels, indicate the typical arrangement of a precast pile.

As indicated in the above drawings, the top and bottom area of the pile is confined by reducing the spacing of the links. It allows the plie to bear the higher loads.

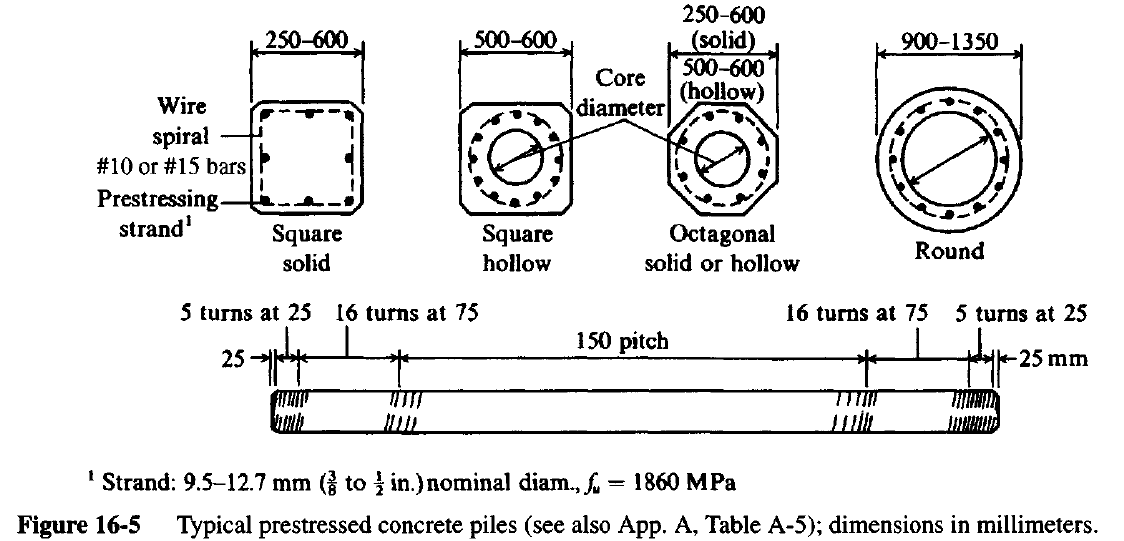

As discussed previously, the prestress pile also used in the construction. The following drawings indicate the typical arrangement of a prestressed driven pile. Especially attention shall be made during the construction of a pile of this nature.

Construction of Driven Piles

Since the precast piles are widely used in the construction, let’s see what are the important aspects of driven piles.

Mainly there are two methods for pile driving.

- The conventional method,

Apply a force on the pile by letting a weight to fall into the pile. The applied load shall be calculated based on the free-fall height of the weight.

It shall be made sure that the applied load will not exceed the capacity of the driven pile.

- Hammer driving methods.

There are three types of driving methods. They are

-

- Diesel Hammer Driving

- Air Hammer Driving

- Vibratory Hammer Driving

Hammer driving methods are easy to use when compared with the conventional method which required more time.

Generally, precast piles are constructed in length 6m due to transportation issues. However, if required they can be constructed even 12m or higher as required.

When 6m driven piles are used and depth to be driven more than 6m, two piles need to be combined. Steel plates embedded at the top of the piles are welded together to increase the length.

The unnecessary length of the pile will be demolished when pile caps are constructed.

Further information hammer driving methods are provided in the Wikipedia article pile driver.

Termination and Acceptance Criteria for Driven Piles

- The pile will be driven up to the hard soil layer that is identified as termination level according to the design. The design and selection of the termination level will be based on the information provided in the soil investigation report.

- When it reaches the termination level, the movement of the pile will reduce.

- The termination and pile driving criteria have established a base on the wave equation analysis of pile (WEAP). Necessary modification to this shall be done at the site as it could vary with the actual ground conditions.

- Further, it is required to record the blow count with the movement of the pile. It could be done as a number of blows to pile to a particular distance or penetration of pile for a particular number of blows. It could be done as per the specification of the project.

- There are limitations to the termination. The specification could provide blow count for given penetration. If it exceeds the blow count to penetrate the specified distance and pile is at the termination layer as per geotechnical data, the pile could be terminated.

Advantages of Driven Pile

- Not like bored cast in situ piles, driven piles can be prefabricated. It minimizes the construction error and adequate quality control can be done.

- Further, any defect such as honeycombs can be repaired in advance before the installation.

- Since piles are driven against the soil pressure, it improves the bearing of the soil with the compaction made by the tip of the pile.

- Less duration and less involvement of labor and machinery till the installations, reduce the cost comparatively.

- In the case of the failures of materials such as concrete, the pile can be removed before the installation. But in bored piles, it will be known only after the construction.

- The pile can be installed inclined to carry the lateral loads. Widely used in bridge constructions.

- The involvement of the technical staff is less.

- There is no impact by the groundwater table on construction.

- The time taken to cast is singe pile is very less. Therefore, more suitable for speedy constructions.

Disadvantages of Driven Pile

- Proper planning is required before starting the construction to handle equipment, site, and transportations.

- They cannot carry heavy loads generally. Therefore, mostly the bored piles are used when the load on pile increases.

- Further, there is a limitation of increasing the diameter of the pile. Higher the diameter, the higher the issues of handling the piles. Transpotatings will be very difficult.

- Structural design shall be checked for the transportation loads. Special attention shall be made for the Prestress concrete piles as the could dame when lifting if it is not considered in the design.

- Since the depth of the pile or length of the pile varies from location to location, the length of the pile cannot be predetermined. Therefore, piles need to be joint and hack the excess.

- When the piles are constructed in the compacted area, the soil could lose and its top bearing could be reduced.

- Noise in the installation process shall be controlled.

- Vibrations shall also be controlled.

- If the length of the piles available is not adequate, they need to connect together to have adequate depth. It could wast pate of the new pile.

- Construction and design of driven piles need to be done for available sizers if they are brought from the market. Otherwise, they need to be made for the required size and length.

- Driven piles could not be suitable for soils with poor drainage properties. A proper geotechnical investigation shall be done to the suitability of driven piles.