The type of connection to be used depends on the nature of the structure and structural design. Out of other connections, moment connection is inevitable in streel structures. It is a very important and very useful type of connection.

Two types of connections can be observed in a steel structure.

- Moment Connections

- Shear Connections or Simple connections

The comparison of these joints is as follows.

| Moment Connection | Shear Connection | |

| Other Names | Fix or Rigid connection | Pined or Hinge connection |

| Forces Transfer in the Connection | Moment and Shear | Shear only |

| Rotation | No relative rotation | Connection can rotate |

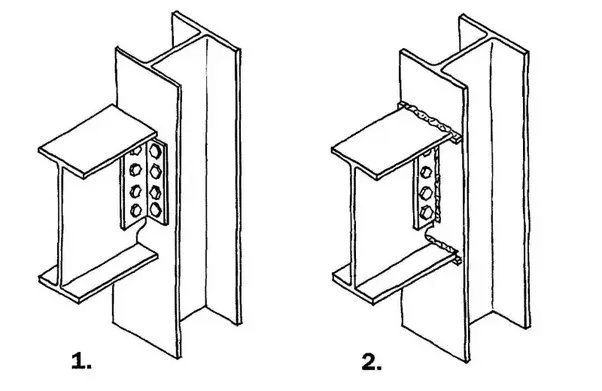

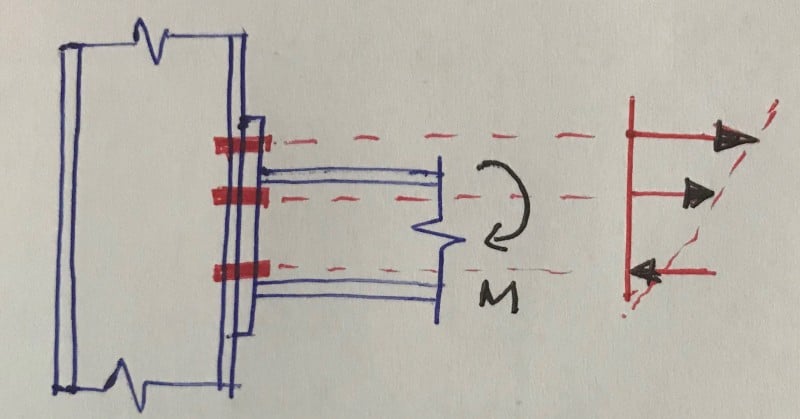

Further, the behaviour of the connection can be indicated in the following figure.

The connection type 1 is free to rotate as the top flange of the beam is not restrained. However, in connection type 2, the top and bottom flanges are connected to the column not allowing relative movement. Since there is no relative movement this connection can be considered a moment connection.

Types of Moment Connections

The nature of the connection is used to define the moment connections. The following types of connections can be considered as moment transferring connections.

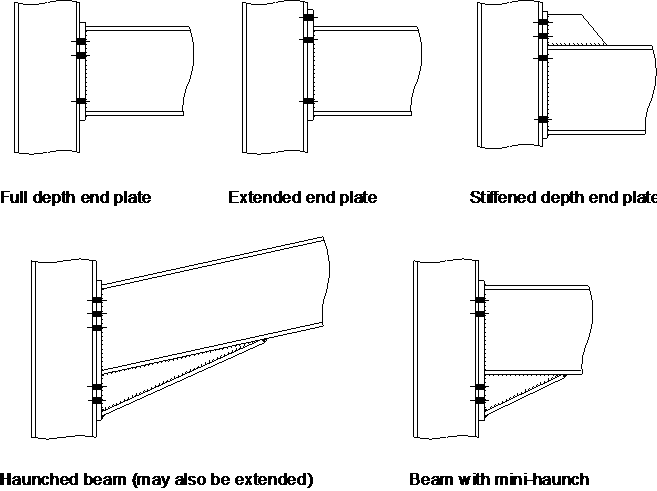

- Bolted end plate beam to column connection

The arrangement of the endplate is the key to transferring the moment from the beam to the column

Fig. form steelconstruction.info

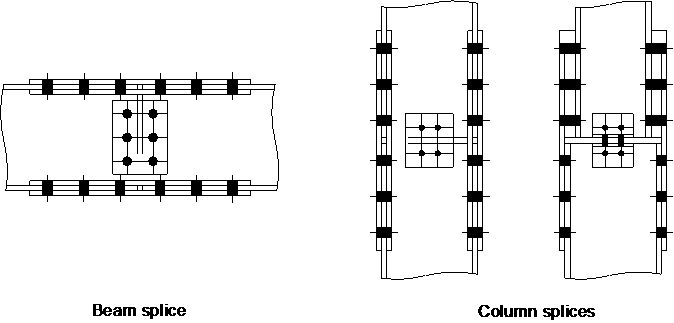

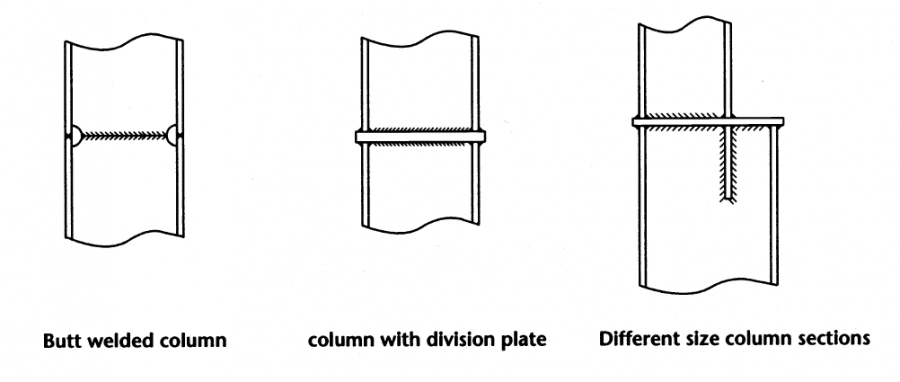

- Splice Connection in Beams and Columns [ Bolted Cover Plate Splices]

Fig. form steelconstruction.info

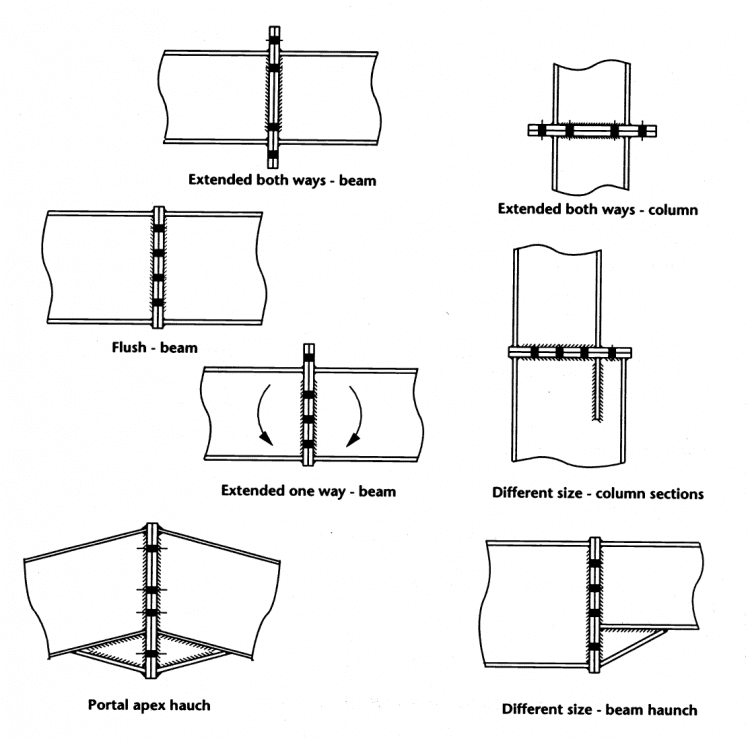

- Splice Connection in Beam and Columns [ Bolted End Plate Splices]

Fig. form steelconstruction.info

- Welded Splices

Fig. form steelconstruction.info

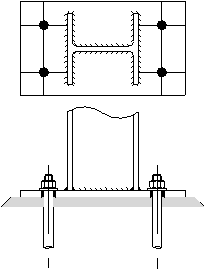

- Column Base Plate Connection

Design of Moment Connections

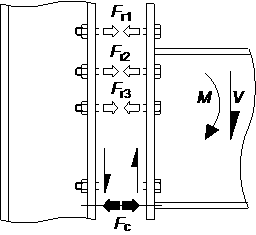

In moment connection, we transfer the whole moment to the other element. No relative rotation is considered. The design moment is considered to calculate the weld length and weld size. In addition, depending on the applied force, bolt compression and tension forces also can be calculated.

The above figure indicates the triangular distribution of the force due to the induced bending moment. Considering the equilibrium of the connection can be used to calculate the bolt tensile forces.

When the ductile behaviour of the connection is considered, full resistance can be obtained. When the connection is ductile, the plastic distribution can be considered. In this case, the tensile forces of the two bolts indicated in the above figure are considered equal.

Fig. form steelconstruction.info

Once we calculate the blot forces, diameter and the bolt grade can be selected. In addition, it is required to check the connecting plate also.

Methods of Strengthening of Moment Resisting Joints

Stiffening plates are added to the moment connection to enhance its capacity and to avoid failures due to the induced stresses.

The following type of column stiffening plates is added.

- Full Depth and Partial depth horizontal stiffener

Purpose: avoid web tension failures, enhance flange bearing and enhance web compression.

- Supplementary Web Plates

Purpose: To enhance the web tension, compression and shear capacity.

- Diagonal Stiffeners (N type and K type) and Morris Stiffener

Purpose: To enhance web tension, flange bearing and web shear.

- Flange Backing Plates

Purpose: To enhance flange bearing.

Weld Moment Connections

Instead of using the bolt connections, weld connections can also be used as a full moment transfer connection. In addition, a combination of bold connection and weld connection can also be done.

The behaviour of the fully welded connection is not the same as the bolted connection. Induced stresses on the column flange and the web could be the same and stiffener plates could be used as discussed above to enhance the section.

The type of the weld and weld size cold be determined based on the applied stresses. Since the length of the weld is fixed for the endplate and column flange connection, the size of the weld could be increased as required.

When weld connections are used, special attention shall be made to the quality of the weld as it solely depends on the weld quality.

Some of Related Articles on Steel Structures Design are as Follows.

- Single Angle Design for Tension as per EC3

- Bolt Connection Design Using Eurocode 3

- Single Angle Section Design Worked Example

- Steel Column Design EC3 Worked Example

- Steel Column Design using Eurocode 3

- Steel Beam Design Worked Example [Universal Beam]

- Lateral Torsional Buckling [Theory and Calculation]

- Steel Beam Design as per BS 5950

- Classification of UB Section as per BS 5950