Non shrink grout is a type of material that does not shrink. This is a cementitious material that does not reduce its volume when it getting harden like normal concrete. The final volume will be greater or equal to the initial volume of the concrete.

Non shrink grout some times called construction grout. It should be noted that it is required to have non shrink property and in addition to the other technical requirements. It sometimes acts as the load transfer medium in structures.

Uses of the None Shrink Grout

There are many applications of the non shrink construction grouts.

- Honeycomb Repair

- Filling under the base plates

- Anchor bolt installation

- Machine base sloe plates

- Steel bearing plates

- Filling cavities in concrete or any structural component

Features of Non Shrink Grout

- No impact on reinforcements

- High bonding strength

- High compressive strength

- High tensile strength

- Pumpable for easy placement

- Early strength

- Above the slab below the slab can be applied

- Can be made as flowable or as a hard mix depending on the application

Important Facts to be Keep in Mind When Using Non shrink Grout

- It is very sensitive to the water-cement ratio. A change in the water-cement ratio will significantly affect the strength of concrete.

- Non shrink grout will be applied where we need the non shrink property. An increase in the water content will affect the performance of the concrete and it could not provide the expected result.

- Higher water content could lead to cracking of the concrete due to the higher drying shrinkages.

- Therefore, attention shall be made to quantities to be used for making non shrink concrete. All the material shall be measured before mixing. Water content, non shrink cement content shall be measured.

- Adding water shall be per the recommendations of the supplier and mixing time shall also be as specified in the product specification.

- Where there is a large volume of non shrink construction grout is required to be filled, adding chips at a mix ratio of 1:1 is the common practice. However, this shall be done according to the supplier’s product specification.

- The depth of filling in a honeycomb is generally limited to 100mm per pour. This shall also be done base on the supplier’s product specification.

Technical Data of Non shrink Construction Grout

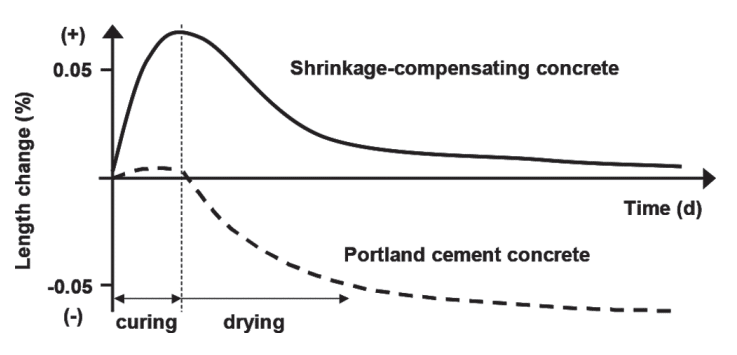

- Curing shall be done at least 3 days

- Quick setting time. If required, loading could be done within 24 hours.

- High characteristic strength of concrete such as 50 N/mm2

- There are three consistency levels such as fluid consistency, flowable consistency and plastic consistency.

- Chloride is free most of the time

- Generally, the maximum thickness per pour is 100mm

- The mix ratio for adding chips is 1:1.