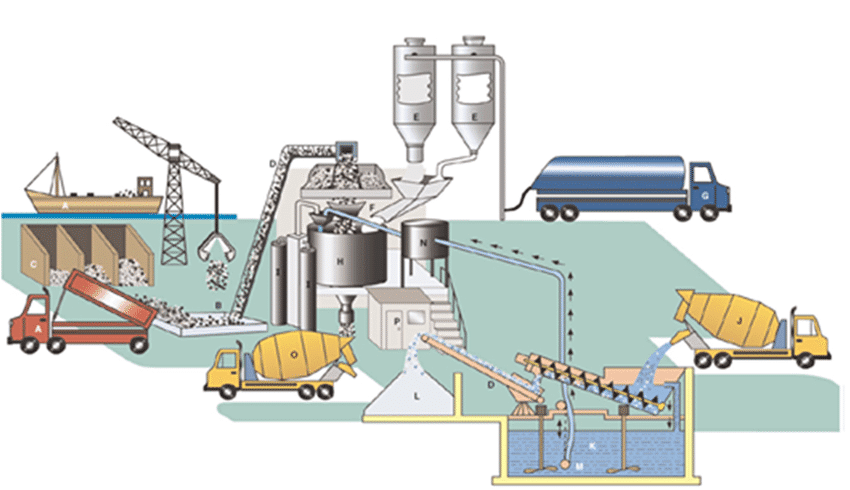

Ready-mix concrete is concrete that makes in a batching plant according to a mix design. Ready-mix concrete is the type of concrete mix used in construction mostly.

Mixing of aggregates (coarse and fine aggregates), cement, water, and admixtures are done to an engineered mix in the batching plant to make ready mix concrete.

After mixing, the mix becomes concrete and it delivered to the site by a truck mixture that maintains the plasticity of concrete until it delivered to the site.

Types of Ready Mix Concrete

Mainly there are three types based not the mixing methods. This classification is also related to when they are mixed.

They are as follows.

- Transit Mixed Concrete

- Shrink Mixed Concrete

- Central Mixed Concrete

Transit Mixed Concrete

This type of concrete is also known as truck mixed concrete. Mixing of the concrete is done in the transit and it is done using the truck mixture.

Mostly the mixing is done partly at the transit and complete mixing is done at the site.

The most important thing in this type of mixtures is that we keep the aggregate and cement mix sperate from the water. Water added and mixing is completed just before the concrete pouring.

This method avoids issues related to workability such as loss of slum, maintain the plasticity of concrete, etc. Further, it avoids the issue caused during the transportation of concrete from the batching plant.

The capacity of the truck could be smaller than the usual truck. Therefore, the quantity of concrete could be smaller per truck.

Shrink Mixed Concrete

Shrink mixed concrete is one of the options that used to increase the volume carried by truck.

Partial mixing of cement, aggregate, and water are done as a measure to reduce the volume.

The complete mixing is done at the transit or at the site. By using this method, the volume that can be loaded in a truck can be increased.

Central Mixed Concrete

This is the type of concrete that is widely used in construction and we mostly know as the ready mix concrete.

Concrete is mixed in stationary plants and loaded in the truck mixture. No mixing is done in the truck though it maintains the continuous rotation to maintain the plasticity of the concrete.

This type of ready mix concrete plant is also known as wet batch or pre-mix plants.

Now, let’s some important factors related to the ready mix concrete.

- Mix Design

Ready-mix concrete is made for engineer mix that is done according to a technical method.

Mostly the ready mix concrete is weight batching where all the quantities of material are put into the mixing bin based on the weight.

Admixtures may be added as per the volume specified by the supplier.

Before start concreting from ready mix concrete in a project, trial mixtures are done to make sure the particular mix has the target strength for that mix design.

- Setting Time

Usually, the setting time of the concrete is about one hour in normal concrete. However, it not sufficient in normal operations.

It will take more than one hour to pure the concrete into the slabs, walls, columns, mat foundation, etc. Further, travel time also needs to be considered as the total time is the count after mixing.

Concrete neet to pore and compact before it inial setting time. Otherwise, the durability of concrete will be an issue. The formation of cold joints could also be observed.

Therefore, admixtures are added to increase the setting time of the concrete.

- Admixtures

Different types of admixtures are added to the ready mix concrete at the batching plant.

The method of adding admixtures are based on the suppliers’ specifications. When different types of admixtures are added to the mixing concrete, compatibility must be checked before the addition.

There is a method called redosing that use to add the admixture to the ready mix concrete in the truck mixture. Especially when the loss of slump is controlled by redosing. If redosing is done it shall be done with much care and getting the consent of the engineer.

Further, there are limitations in adding any admixture to the concrete. The maximum limit specified by the supplier shall not exceed in any case.

- Slump at Batching Plant and at Site

Athe mixing the concrete it is loaded in the truck mixture from which a sample is taken to check the slump. The slump at the plant is recorded in the delivery note that needs to produce to the engineer at site. This record provides an indication of the slump of the mix.

When the ready mix concrete is delivered to the site, a slump test is carried out to check the slump at the site. The slump at the site is the design slump that specified in the mix design. If it is within the limits, concrete can be used if other requirements are acceptable.

- Concrete Temperature

The temperature of the Ready-mix concrete needs to be controlled in order to have a low heat of hydration. Therefore different actions are taken in order to reduce the temperature of the ready mix concrete.

Some of them are as follows.

-

- Use Chilled water for concrete mixing.

- Cooling the aggregates

- Add Ice to replace some volume of water

- Colling the truck mixture concrete container – place gunny bags and apply water

- Aggregate

Once a mix design is done and trial mixtures are done(tested cubes for 7 days and 28 days strength) for the same, no changes in the aggregate shall be made.

As we know, if we change the material sources, (not only the aggregate but also other additives) mix design will be changing and the results obtained from the trial mix will no longer valid.

Further, since we are using new generation superplasticizers as admixtures, changes in the sources of the materials will adversely affect the concrete mix as they are very sensitive to the changes.

Therefore, no changes shall be made in the source of materials once selected and finalized by a trial mix testing.

Advantages of Rady Mixed Concrete

- Quality of Concrete: Not like other methods, all the mix propositions are added accurately without an error. Further mixing is done in a controlled manner and adding water and admixtures are also done as per the technical requirements. Therefore, we can have a quality mix.

- Consistency of the Ready-mix Concrete: Consistency of the concrete mix can be maintained whether we mix 20m3 or 200m3. Since all the work until it is loaded to the truck mixture, by mechanical and electronic equipment, the possibility of occurring errors negligible.

- Quantity of Production: There is no limitation for minimum quantity or maximum quantity. Production can be made based on the requirement of the project.

- Efficient of Production: Production of concrete can be done more efficiently. The rate of the product will depend on the size of the mixing bin. However, production can be done continuously till the planned work is completed. Further, the time taken to produce a one-meter cube of concrete is less when compared with other manual methods.

- No Material Storage at Site: No space allocation is required at the site when the batching plant is not located at the site. On some occasions, especially in major protects, batching plants are established at the site due to the construction demand. In such situations, we need space for material storage.

- Material Saving: Since the materials are used in a controlled manner, wastages are minimal. Especially the cement is stored in the silo and no wasting when it taken to the mixing bin or into the silo.

- Environmental Impact: Environmental impact of the production method is minimal. No gas burning is required as all the equipment is working from the electricity.

Disadvantages of Ready Mixed Concrete

- Effect on the Setting Time: Mostly the batching plants away from the construction site. Therefore, it will take some time for the concrete mix to receive to the site. The setting time of the concrete should be adjusted accordingly. Further, traffic congestion could also be affected by the time to reach the site.

- Slump Loss: When there is a considerable distance to the site, there will be a loss of slump. It is the loss of the workability of the concrete. Therefore, mix desing shall be done in a manner that the loss of slum due to the travel distance could not affect concrete pouring.