Rebar is also known as reinforcing bar, reinforcing steel, and reinforcement steel is the material that is used in concrete to enhance the flexural strength of the concrete element.

In history, before the invention of the reinforcement steel, different techniques are used to carry the tensile stresses due to the action of load, or structural form was modified in a way that it does not develop the tensile stresses.

The best example is the arch. It was used as a compression element that carries the loads as compression loads or as axial compression.

The use of the rebar bar in construction extends up to the 15 century for masonry structures. Initially, they mostly used in masonry structures to enhance their capacity. The changing point in the use of the rebar in construction is the 19th century with enhancing its strength by embedding it in the concrete.

Enhancement of the strength of the reinforcement steel further popularizes as it was able to develop strong reinforced concrete elements.

Why Rebar in Concrete?

Concrete strong in compression and is weak in tension. Generally, the tensile strength of concrete about 10% of its compressive strength.

When the concrete subjected bending action, there is compression and tension in the section. Tensile stress will be carried by the reinforcement and concrete will carry compressive stress.

In addition, when concrete cannot carry the axial stress, we add reinforcement steel to carry the balance stress.

Development of Reinforcement Steel Technology

Early days steel does not have the strength like the reinforcement we use today. Now we have reinforcements that having the strength of 500-6000 N/mm2.

The following table shows its development.

| Bar Type | Introduction Year | Yield Stress/MPa |

| Plain round | 1895 | 230 |

| Deformed | 1920’s | 230 |

| Square twisted | 1957 to 1963 | 410 |

| Intermediate grade deformed | 1960 to 1968 | 275 |

| Hard grade deformed | 1960 to 1968 | 345 |

| Twisted deformed | 1962 to 1983 | 410 |

| Hot-rolled deformed (410Y) | 1983 | 410 |

| Hot-rolled deformed (400Y) | 1988 | 400 |

| Hot-rolled deformed (500Y) | 2000 | 500 |

In today’s construction, there are four main types of reinforcement steel bars.

- Mild Steel

- Tor Steel

- TMT Steel

Properties/Characteristics of Rebar

Mainly there are three types of concrete reinforcement steel we used in construction as discussed previously. We characterize these steel based on their strength.

Yield strength or 0.2% proof stress is used to characterize the reinforcement bars. Accordingly, the following categorization is made based on yield strength.

| Rebar Type | Yield Strength / N/mm2 |

| Mild Steel | 250 |

| Tor Steel | 460 |

| TMT Steel | 500/550/600 |

Let’s what is the main difference between TMT steel and TOR steel.

Difference between TMT bars and TOR Steel

- Tensile Strenght

TMT bars have higher yield strength than the TOR steel as indicated in the above figure.

An increase in the yield strength reduces the area of reinforcement to be used leads to the reduction of the cost of construction.

- Ductility

Ductility is the ability to withstand without failure when it subjected to higher loads.

TMT bars are more ductile than TOR steel due to the inherent properties of the bars.

- Elongation

TMT bars have higher elongation due to the crossectional properties. The hard outer layer and soft inner layer allows it to elongate without failure.

- Weldability

Low carbon content in the TMT bars allows it to weld without changing its material properties. Further, the hard outer layer allows it to withstand as it is with the rise of the temperature when welding is done.

Chemical Composition of Rebar

The carbon equivalent value is the parameter mainly used to check the chemical composition of the concrete reinforcement steel.

Ceq = C + Mn/6 + [Cr + Mo + V]/5 + [Ni + Cu]/15

Where, Mn – percentage of manganese content, Cr – percentage of chromium content, V – percentage of vanadium content, Mo – percentage of molybdenum content, Cu – percentage of copper content, and Ni – percentage of nickel content.

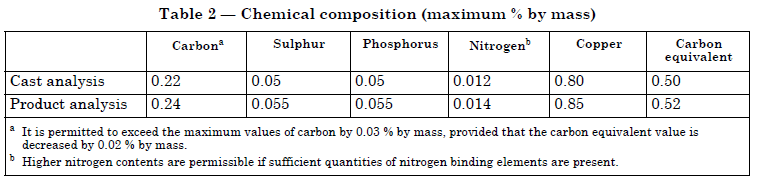

The following table taken from the BS 4449 indicates the allowable carbon equivalent value for Cast analysis and Product analysis.

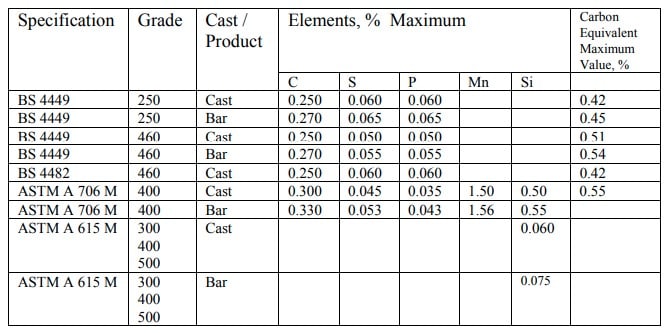

Let’s see a comparison of other standards as well. There are different values allowed by ASTM when compared with the BS 4449.

The following table extracted from the technical document provides a clear indication of the variation of values.

Dimension of Reinforcements

The standard diameter and cross-sectional area indicated in the flowing table as specified in the BS 4449:2005 shall be used in the calculations for quantities or for design requirements.

Further, mass to be calculated following the table.

| Nominal diameter/mm | Cross sectional area/mm2 | Mass per metre/kg |

| 6 | 28.3 | 0.222 |

| 8 | 50.3 | 0.395 |

| 10 | 78.5 | 0.617 |

| 12 | 113 | 0.888 |

| 16 | 201 | 1.58 |

| 20 | 314 | 2.47 |

| 25 | 491 | 3.85 |

| 32 | 804 | 6.31 |

| 40 | 1257 | 9.86 |

| 50 | 1963 | 15.4 |

Allowable Tolerances in Reinforcement Steel – BS 4449:2005

- Length

The permissible deviation from the nominal length shall be +100 / -0 mm.

This means, length could be increased by 100mm but it is not allowed to reduce the specified length.

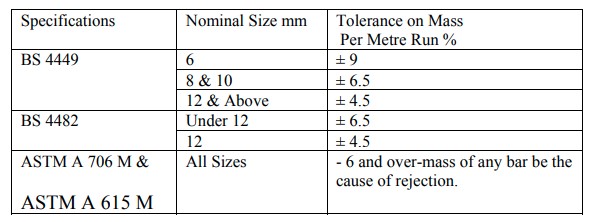

- Mass

The permissible deviation from the nominal mass per metre shall not be more than ±4.5% for nominal diameter greater than 8mm and ±6% for nominal diameter less than or equal to 8mm.

However, according to the other standards, there are slight deviations in the values as shown in the following figure.

- Surface Geometry

The arrangement of the ribs and their dimensions and angles shall be as specified in BS 4449. The same have discussed in the article rebar rib could be referred for more information.

Rebar Testing

Mainly the are two types of testings are done for the reinforcement. The sequence of the testing of reinforcement shall be as per the relevant standards.

- Check Chemical composition – Chemical analysis of steel bars

- Check Physical properties – strength and elongations

Routing inspections and testing are done to maintain the quality of reinforcement at the production and at the site.

BS4449:2005 specify the following verification criteria/rate for bars and coils.

- Chemical composition: One analysis per test unit and cast analysis should have done by the steel producer

- Rebend tests, nominal mass per metre, and surface geometry: one test piece per test unit and nominal diameter.

- Tensile Tests: one test piece per 30tons with at least three test pieces per test unit and nominal diameter.

Chemical Composition – Chemical Analysis of Rebar/ Cast Analysis

As discussed previously, we check the chemical composition of the steel and calculate the carbon equivalent value.

In these tests, chemical analysis will be done for all the types of reinforcement bars. The sequence of testing shall be as stipulated in the relevant standard or project specification.

This test normally will be carried out for one analysis per test unit.

Chemicals such as C, Si, Mn, P, S, Cr, Mo, Ni, Cu, V, etc are checked and carbon equivalent value is evaluated using the relevant chemicals as shown at the beginning of the article. When the produced analysis is done, it should be less than 0.52.

The maximum values specified for product analysis for chemicals; Carbon(0.24), Sulphur(0.055), Phosphorus(0.055), Nitrogent(0.014) and Copper(0.85) are checked in addition to the carbon equivalent value.

Physical Properties

It is a must to check the physical properties of the reinforcement bars during the production and during the construction.

Mainly, there are three types of tests that are done from the sample taken from the reinforcement brought to the site.

- Tensile Properties

- Rebend Test

- Rib Geometry

Tensile Properties

The following parameters are checked under the tensile properties

- Yield strength

- Tensile strength

- Percentate of elongation

- Crossectional area

- Mass per meter length

It is checked the above parameters are within the acceptable limits as discussed in the initial part of this article.

There are various types of reinforcements

Types of Rebar

- European Rebar

- Carbon steel rebar

- Epoxy coated rebar

- Galvanized rebar

- Glass fiber reinforced polymer(GFRP)

- Stainless steel rebar

The following articles are related to concrete reinforcement. Worth studying for the knowledge.