It is required to remove rust from rebar before starting the construction work. Actually, before concrete, rebar rust should be cleaned adequately if it has started corroding.

The following reasons could cause reinforcement corrosion.

- Keep a longer duration exposed to the environment.

- Continuous wetting and dry at the site due to inadequate protection.

- Kee the reinforcement exposed at a site close to the sea. Rapid corrosion can be expected if they are not covered properly.

What is the reinforcement corrosion?

Reinforcement corrosion is the major deterioration method of the reinforcements.

In the presence of the oxygen and moisture corrosion of steel occurs. It starts to deteriorate the material forming rust on the surface.

Further, corrosion of the reinforcement creates further deterioration of reinforcement and losing the dimension of the reinforcement bar.

Why should Remove Rust from Rebar

Having rust on the surface of the rebar could cause further corrosion of the reinforcements.

Further, placing concrete with the rust in the reinforcement, lose the bond between the concrete and reinforcement bar.

It could lead to reducing the bond strength.

In addition, if the concrete is placed without cleaning the rebar, further corrosion of the reinforcement could start at the presence of moisture and oxygen.

As we know, concrete gets cracked due to durability issues. Such cracks could create the environment required for corrections of steel.

Therefore, no concrete shall be placed without cleaning the rebar.

How to Remove Rust from Rebar

Nature of the corrosion and the degree of corrosion considered to select the method of removing the rust from rebar.

Further, the cost of the cleaning process will also increase when the corrosion is very high.

Wire Brushing

Wire brushing of rebar can be done manually or with machines.

If the reinforcement is tied at the slab, they can not be cleaned with machines unless they removed from the slab.

When the reinforcement is not tied in the slab and if there is a cleaning matching, it is advisable to clean the reinforcement with a machine.

Further, minor stage rust could be removed manually. When it is not spread in the whole bar, it can be cleaned with a wire brush.

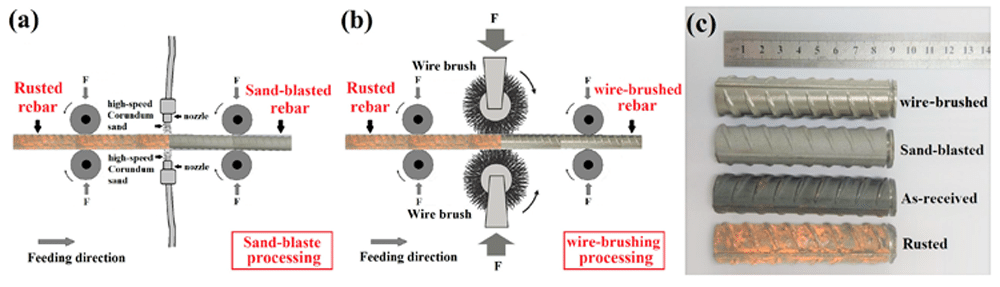

The following figure indicates the cleaning process of rebar.

Part (b) of the above figure indicates the cleaning of rebar by wire brushing.

Use High-Pressure Water Jet to Remove Rebar Rust

When the corrosion is not that significant where a thin layer of rust is present on the surface of the reinforcements, water jetting can be used to clean.

High-pressure water can be applied to rebar consistently to remove the rust layer.

This shall be done with many patients and it shall be made sure the whole surface is cleaned.

Further close supervision shall be done during the cleaning process. When the reinforcement is wet, it is very difficult to identify whether the rust is removed.

If not cleaning has to be done again and again until reinforcements are properly cleaned.

The following video indicates rebar cleaning.

Apply Chemicals to Remove Rebar Rust

There are chemicals that can be used to remove the rust from the reinforcements.

Firstly they are applied to the reinforcements.

Then they are kept for some time to react.

After that cleaning will be done. The method of cleaning could be an injection of water or any other method. The product supplier’s specifications shall be followed in this process.

When the quantity of reinforcement is higher and if we are using branded products, the cost of the cleaning process will be higher.

However, whether it is costly or not we have to clean the rebar. A suitable method with a low cost could be selected.

Sandblasting Rebar for Remving Rebar Rust

Sandblasting is not widely used for cleaning of reinforcements. It is generally used to clean corroded steel.

However, when the reinforcement is heavily corroded, it will be very difficult to clean them adequately. Therefore, it is required a fast method to clean the reinforcements.

Manual wire brushing or application of chemicals is a bit difficult process and time-consuming.

Further, guarantee on the cleaning is also sometimes doubtful. If the application of chemicals is not in the whole bar, such areas will not be cleaning.

When compared with those things, sandblasting is a good option. The following video indicates the sandblasting.

As done in the above video, rebar can be cleaned onsite and they can be clean at the store.

It is advisable to cover the area to be used for cleaning of rebar to avoid dust flowing everywhere.

Apart from above, if reinforcement is corroded heavily, it is advisable to protect the reinforcement from corrosion. A suitable anticorrosive shall be applied to the reinforcements immediately after cleaning.

Further, a higher grade of concrete could be used to improve the durability of concrete structure.

In addition, if the construction is close to the sea, chloride resisting cement could be used to improve the durability.

Further reading on sandblasting also known as abrasive blasting from Wikipedia article Abrasive Blasting.