The slump test of concrete is the measure of the workability of concrete. It is the only indicator that is used to know the condition of concrete until it is tested for strength.

It provides several indications of the condition of the concrete. Some of the following could be considered together with the slump test.

- Low slump indicates low workability of concrete. If the concrete is having low workability, it is a kind of indication of an issue with the concrete.

- If there is a very high slump, it could be due to the high-water content. In addition, if high range water reducing admixtures is used and excessive dosage could also result in that.

- Low slump, which is not within the limit, could be due to the low water content. In addition, checking the slump after considerable time also could show a low slump.

- Use of high-range water-reducing admixtures could also result in a rapid drop in the slump after a certain time.

- Further, the texture of the slump test concrete having low slump could also be used to just the issues with the concrete.

Therefore, doing the slump test for the concrete mixture is very important.

How to Test Concrete Slump

The following procedure could be followed to carry out a slump test of concrete.

- All the concrete trucks are tested with a slump. This is done at the batching plant and the site.

- Place the cone on a flat surface that is not poured. When the slump test of concrete is done at the site, a steel place could also be used.

- Cone shall be filled with three layers (stages) and each layer shall be compacted with 25 strokes.

- Once the cone is filled, remove the excess concrete and level the top surface. Also, remove the concrete fallen around the cone.

- Lift the cone at a gradual rate until it moves away from the concrete and places the cone next to the concrete. The cone is generally placed upside down.

- Place the rod on the cone and measure the gap between the rod and the concrete. This is the concrete slump.

Let’s see the behavior of the slumps

Types of Slumps

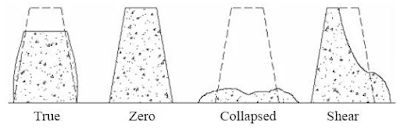

Mainly four types of concrete slumps can be observed.

- True Slump

The concrete follows the same shape as the cone and indicates a certain slump. This can be seen in most of the time, and a true slump within the acceptable range specified in the mix design, can be used for the construction.

- Zero Slump

The concrete follows the same shape as the cone and there is no very smaller movement in the vertical direction.

Depending on the nature of the construction, and as specified in the concrete mix design, rejection or acceptance of the concrete mix will be done.

- Shear Slump

The top part of the concrete collapse in the shear slump. This could be due to the low cohesion of the concrete.

In addition, the higher workability of concrete also could lead to this kind of collapse during the slump test of concrete.

- Collapse

The complete collapse of the concrete is called the collapse slump. This could be due to the higher workability of concrete.

Higher water content, the issue with admixture used for concrete, etc. could be the reason for these types of issues.

In general, if the concrete does not meet the specified slump by the concrete mix design will be rejected. Generally, higher slump concrete beyond the specified limit could not be able to use.

However, concrete with low slump having added admixture could be modified with redosing if it is allowed as per the product specification. In addition, it shall be made sure the maximum allowable dose has not been reached.

Standards for Slump Test of Concrete

- British Standards, the slum test can be carried out as per the following standards

BS 1881-102

- According to the European Standards, a concrete slump can be tested as per

BS EN 12350-2

- According to the ASTM standards, a slump test of concrete can be done as per

ASTM C143

Factors Influence the Concrete Slump

The following factors can be identified as having the most influence on the variation of concrete slump.

- Material Properties

Types of aggregate used and their gradation, shape, etc.

- Admixtures

Admixtures are highly influential for the slum of the concrete or the workability of concrete.

Generally, superplasticizers are being used as high range water reducing admixtures to get the required workability of concrete. Using the admixture without a trial test or over dosages could lead to issues in the workability of concrete.

- Percentage of air entrapped in the concrete

- Time of concrete

The time is taken after the concrete has mixed.

- Water Content

Depending on the purpose of concrete use, there are different slump classes, and the same concrete mix design is done. During the construction, we have to make sure the specified slump is there.