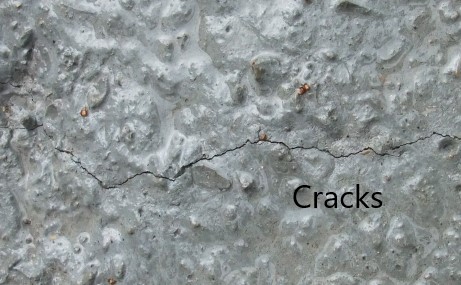

Thermal cracking of concrete needs to be avoided especially for the thickness of concrete is increasing. Let’s what types of thermal cracks exist.

Commonly known issues faced by the designers and the construction team is the cracking due to the thermal effect. The increase of heat in the concrete is inevitable though it can be controlled or minimized up to some extent. Further, providing reinforcement calculated based on the design assumptions is also an action that can be taken to solve the issue. Cracking of concrete can be discussed under the following categories.

- Freeze/ thaws cycles

- External seasonal temperature variation

- Early thermal contractions

Cracking due to Freeze/thaws cycles

Water molecules in the concrete freeze and as a result the volume increases than the contained within the concrete.

Damage caused due to this process is identified as freeze/thaws damage. When the content of the water in the concrete is greater than 91%, it is called saturated concrete.

When saturated concrete is frozen, its volume is increased by 9%. Since there is no space to accommodate the increase of the volume, concrete subjected to additional stress. As a result of this, the following could be observed.

- Cement and aggregate could be debonded

- Concrete can crack (random cracking)

- Surface scaling

- D-cracking (durability cracking)

The impact of Freeze/thaws effects is due to the following reasons and it could be minimized as suggested therein.

- Inadequate entrained air. If there is sufficient air to cater to the volume increase, first thee issues in the above list could not rise.

- Use of the nondurable causes the D-Cracking. Therefore, it is recommended to avoid it.

- High water-cement ration also directly supporting this issue. Therefore, limiting the content of water with the use of water-reducing admixtures could be done.

Cracking Concrete due to External Seasonal Temperature Variation

Structures are exposed to the direct sunlight subjected to change in temperature considerably when compared with covered structures. Thye absorbs the heat and releases it at the night. Rise of the temperature is depending on the environmental conditions.

Heating expands the concrete and colling contract the concrete. When it heated the tensile and compressive stress are developed and the same process can be observed during the colling also. As a result of this, the thermal cracking of concrete develops with time as the stresses are developed usually.

Craking of concrete due to the external seasonal temperature variations can be minimized if it was considered at the design phase.

Depending on the stress developed due to the applied loadings, reinforcement is calculated for a section. There will be additional stresses due to the variation of the temperature in the section. It has to be taken in to account at the reinforcement design.

Different load combinations to encounter the thermal effect can be considered for the design.

Limitation of design crack width could be done for the following loading combinations.

A structure is subjected to bending moments (M), axial forces (T – tensile forces; causes cracking) due to the loading in addition to the Temperature variations such as the rise of temperature from ambient temperature during the hydration process (T1) and variation of temperature due to seasonal effects (T2).

- Crack width (M + T + T2)

- Crack width ( T1 only)

- Crack width ( T1 + T2)

When designs are done considering the above cases, cracking can be minimized.

Early Thermal Contractions

Early thermal cracking occurs due to the excessive tensile strains in the concrete than its capacity, and tensile strains are developed due to the thermal contractions or with the variation of temperature within a section. The development of the thermal cracking of concrete could be extended up to two to three weeks.

The reaction between the cement and the water generates the heat. The amount of heat and the rise of the temperature depends on many factors.

- Type of cement

- Quantity of cement

- Placing temperature(temperature of concrete at the time of pour)

- Ambient conditions

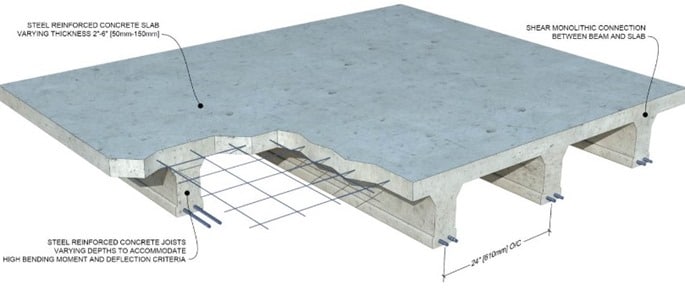

- Geometry of the member including the thickness of the concrete

- Type of formwork

Concrete reaches its peak temperature with its first day and then it starts gradually cooling down. The following figure indicates the variation of the temperature done at mockup tests when there are concerns on the type of forme work to be used, the maximum temperature at the core, temperature gradient, temperature difference between the core and the formwork, etc.

As discussed above, there are many reasons for the development of additional strains in the concrete. Therefore, it is recommended to check the variation of the temperature of the concrete by mockup test when the element sizes are larger; 1000mm, 1500mm, etc. and the grade of the concrete also higher. Cement content is increased with the increase of grade of concrete, as a result, the heat of hydration will be higher when compared with low-grade concrete.

The following factors can be considered as the major issues for causing the early thermal cracking.

- Temperature rise

- Thermal expansion coefficient of the concrete

- Ability of concrete to retain the tensile strains

- Internal and external restains

Early thermal cracking can be avoided by the design reinforcements to a certain extent. Reinforcement calculations shall be done based on the relevant restrains and the variation of the temperature during the hydration process. Peak temperature during the hydration process and ambient temperature are considered for these calculations. In addition, the following limitations and actions are taken after doing the mockup test. During the test, it is also checked whether the specified values are met.

- Concrete, when placed, shall have a temperature of not more than 300 C. [Could depend on the project]

- The maximum rise of hydration temperature of concrete shall not exceed 700 C. [Commoly this value is used. However, it may vary project to project and the value can be increased as suggested by different references. Thus, a maximum limit of the peak temperature could be considered up to 80o C with having fly ash+silica fume content greater than 30% to minimize the riks of delayed ettringite formation. However, deviation from the general value (70o C) will always create uncertainty. Therefore, it shall be done under the advice and supervision of the technical experts.]

- No temperature gradient within concrete shall be allowed to exceed 200 C, at a distance of 1 m and the maximum temperature difference between two parts of the same pour shall not be allowed to exceed 250 C. [ Both the limiting values shall be as per the relevant project specification. These values may change slightly with the specification]

- Portland cement with fly ash or low-heat Portland or Blended Hydraulic cement complying with the requirements of relevant standard for cement may be used to achieve the above requirements, in addition to other measures required for temperature controlling in concreting (i.e. use of ice or chilled water for concrete mixing special curing/insulation methods during hydration of concrete).

- Contractor shall be made a sample concrete block of 2mx2mx2m [Size maybe change and could depend on the actual element sizes] using the design mix for the concrete and shall demonstrate the temperature increase variation during the process of hydration to verify the suitability of the mix design and other temperature controlling measures for the use in the shielding structure.

- The contractor shall submit a method statement detailing all the measures adopted to achieve above temperature control measures at least two months before the concrete work of shielding structures for the Engineer approval.

Apart from above, special attention shall be made on the formation of the delayed ettringites as it can cause severe damage to the structural strength. Necessary verification, selection of the type of formwork that full fills the above requirements shall be done.