Concrete blocks are widely used in building construction. It is comparatively more economical than the other types of partition walls.

Concrete blocks have a comparatively good shape and the change of making error during construction is minimal. Further, it as adequate strength to used a load-bearing wall. Further, the ability to use minimum thickness for plastering and wastage of material, really availability, speedy construction, etc has made the concrete blocks more popular in the construction industry.

Application of Concrete Blocks

In construction, today, we can see the wide use of concrete blocks in the construction.

Let’s list the major application of the theme.

- Used to construct partition walls, perimeter walls, etc in the building construction.

- Used as formwork for pile caps, ground beams, etc

- Widely used for cavity walls construction.

- Basement wall construction

How to Make Concrete Blocks

Concrete blocks shall be manufactured in accordance with BS EN 771: part 3 and they shall be checked in accordance with BS EN 772.

Not like the old days, we have machines to make the blocks much easier. Quality control can be done without much difficulty when we used machines for production.

Let’s see what are the material to be used

- Cement

- Water

- Aggregate

Various types of aggregates can be used in block production. Mainly we used crushed stone, gravel, volcanic cinders, foamed slag, furnace clinker, etc.

Aggregates shall be checked regularly to assess the conditions and it shall be made sure they are within the approved gradation.

In the conventional method, we do the mixing and put into the mold, and when it is completed. This method is time-consuming and even quality control is very difficult.

Further, it is very difficult to maintain consistency when it is done manually.

However, when the machine is used, it quite easy and we can achieve good results. Further, depending on the capacity of the machine, we can make many blocks at once. Further, better and consistent compaction can be achieved through the machine.

In summary, the following steps can be highlighted as the manufacturing process of the concrete blocks.

- Select the materials according to the to mix propositions

- Mix the materials. Mechanical mixing can be done to get a consistent mix.

- Vibrate the for better compaction

- Continue curing

The minimum compressive strength of non-load bearing blocks could be maintained greater than 7.5 N/mm2 and load-bearing walls 12.5 N/mm2.

Types of Concrete Blocks

Mainly there are two types of concrete blocks depending on how they look like other than the mechanical properties.

- Solid Blocks

Normally blocks have a rectangular solid shape. Usually, they are available in widths 100mm, 125mm, 150mm, and 200mm.

- Hollow Concrete Blocks

As the name implies, it is a hollow section with a regular shape. They are also available in the same widths as solid blocks. Less weight, less coss, less cost of the structure, etc have made the use of this type of hollow block.

There is no much to discuss the types of solid blocks. However, there are many types of concrete blocks made as hollow blocks.

Hollow Concrete Blocks

As discussed above, hollow blocks are more popular in building construction due to the many advantages brought to the project.

Due to the hollow shapes, it reduces the heat transfer, works as a sound barrier, etc. and those holes can also be used to carry the services such as electrical conduits, pipes, etc. These types of concrete blocks are readily available in any market and they can be made easier with modern equipment in a shorter period of time.

There are different types of hollow blocks.

Let’s discuss them one by one.

Stretcher Blocks

The most widely used type of hollow blocks and are used to joint the corners.

The placement of the blocks is the same as the other types of concrete hollow blocks.

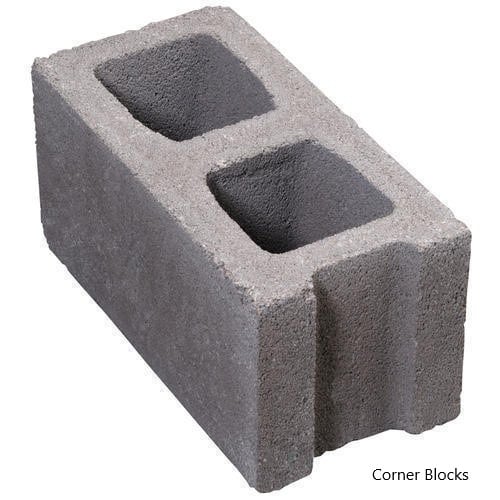

Corner Blocks

They are used to construct the corners or the ends of the block walls.

Partition Blocks

This is a special type of block that can use used to construct the partition walls. Since the use of solid blocks increases the cost of construction, we can do the construction at a reasonable cost.

Further, we can achieve the same properties as the solid blocks of it completely finished.

Lintel Blocks

They are specially made to construct the lintels.

There is a grove in the block and once it is placed in the location, we can do the concreting after adding the required area of reinforcements.

Pillar Blocks

They are also known as double corner blocks as both sides are plain finished. When there is no continuation of the wall on either side of the block, we use the pillar type hollow blocks.

Further, it works as the columns and if required, we can add reinforcements in the two vertical holes in the pillar. Further, after placing all rebar, etc, it can be filled with concrete.

Frogged Brick Block

This is a special design and it is used to improve the good bonding between the bricklayers.

Since the level is lowered in the middle part of the block, we can add mortar which provides the strength and the bonding.

In addition, they can be used as an architectural feature.

In addition, there are several other types of hollow blocks such as bullnose block, jamb concrete blocks, etc which are used on special occasions.

Advantages Blocks

- Lightweight especially the hollow blocks

- Stronger than the normal brick

- No changes in the dimensions, perfect shape

- Easy handle and lesser wastages

- It increases the floor areas the width of the wall is comparatively smaller.

- Better thermal insulation

- Good fire resistance

- Good sound resistance

- Fast construction

- Readily available

- Can be produced in bulk quantities with the construction demand

Disadvantage of Blocks

- Low stiffness in the hollow blocks

- No embedded conduit can be placed on the hollow block walls. They need to place within the hollow section during the construction.

- All the embedment to be made shall be placed before the construction and they shall install wit the construction.

- It is very difficult to construct bathrooms with hollow blocks. In usual construction, we cut grooves in the walls and place the pipes. However, it cannot be done in the hollow blocks.

There is a alternative such as fly ash brick for the block and brick construction. The article wirtten as fly ash brick could be reffered to more information.