Different types of concrete joints are provided in construction depending nature of the construction as required by the design.

In general, there will concrete joints in most of the structures constructed as we cannot construct a structure by one pour.

Depending on the nature of the structure and base on the construction requirements, the following types of concrete joints are provided in structures.

- Movement Joints

- Contraction Joints

- Expansion Joints

- Sliding Joints

- Construction Joints

- Temporary Joints

- Isolation Joints

Movement Joints

As the name implies, the joint is provided to allow for movement between two structures or two components of the same structure.

Movement of the could be due to the following reasons.

- Lateral loads on the structures

The lateral load could be earth pressure, water pressure, wind pressure, earthquake pressure.

When the lateral loads are applied structure could move permanently or temporarily.

The application of earth pressure, water pressure, could move the structure permanently.

However, wind pressure, earthquake load, etc deflect the structure temporarily when loads are applied and then it comes to the original position.

- To accommodate the separation of Irregular structure

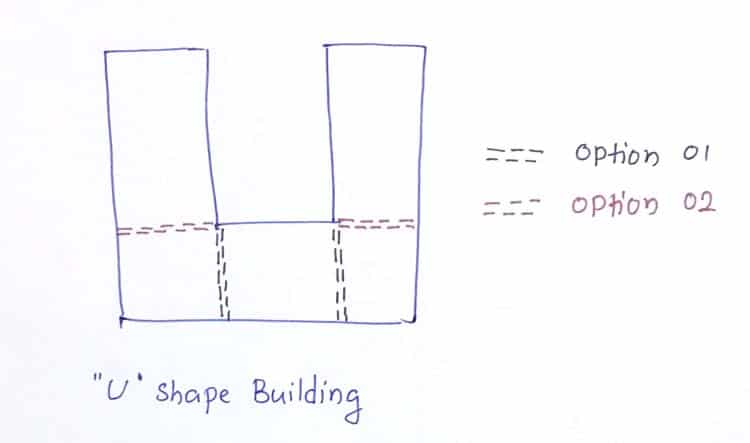

For example, when the building is in “U” shape in plan, it is advisable to have a separation joint in the building especially when it constructed on a shallow foundation.

There will be a different settlement in the structure due to the geometry of the structure. As a result, if the structure is built continuously, additional stresses will apply to the structure.

It can be avoided by operating the structure as indicated in the following figure.

As indicated in the above figure, the movement joint can be constructed based on the preference of the structural engineer.

Movement joints are provided in different structures and the type of joint detail is different from the structure to structure. Further, the gap allowed in the joint will also be a function of the structure type and its use.

- Movement Joints in Foundations

- Movement Joints in Floor Slabs

- Movement Joints in Beams

- Movement joints in Bridges

Movement Joint in Foundations

Many structural inputs are required for deciding these types of concrete joints. The location and nature of the movement joint to be provided in the foundation will be based on allowable movements in the structure.

In general, the width of the movement joint could vary between 10mm -25mm. However, on special occasions, this even can increase up to about 100mm.

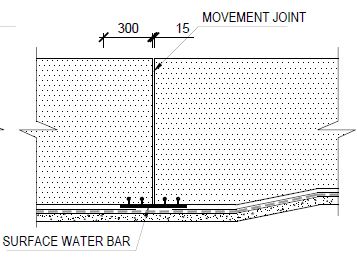

Foundation movement joint especially when there are basements, needs to be water tightened to avoid movement of water through the joint.

When there is a movement joint in foundations such as a raft foundation, a surface water bar will be provided not allowing the penetration of water through the joint.

As indicated in the above figure, it is more appropriate to place the water at the bottom rather than having it at the middle of the section.

Movement Joints in Concrete Slabs

When there is a movement joint in the foundation as discussed above, the same joint will be continued for the floor slabs as well. Further, the width of the joint could also follow the same.

However, when the two blocks are separated by a movement joint for seismic even, it should be careful when deciding the with of the joint.

Width of the movement joint shall be based on the outcome of the structural analysis for such lateral loads applied by an earthquake.

The maximum deflection of the building shall be checked especially at upper levels where it critical, to finalized the width of movement joints on the floor.

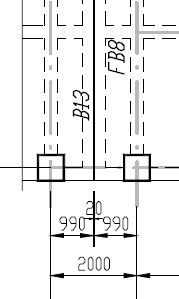

In general, there will be two columns nearby and either side of the movement joint, Both sides could be cantilever to have a movement joint in the floor.

Further, there are other aspects also to look into when deciding the width of the movement joints. The nature of the installation in the joint will also need to be considered when it is finalized.

There are many types of joint sealing methods from joint filler to complex mechanical systems. Depending on the suitability and affordability of cost could be the other factors to be considered.

In addition, these movement joint sometimes identified as expansion joints. However, the function or the purpose of the joint shall determine the type.

The construction joint details used for the expansion joints could also be used for the movement joints. It is only required to make sure that the joint can allow sufficient movement.

Movement Joints in Beams

The same procedure followed for having movement joint in concrete slabs will be used for the beams.

The same gap and embedment details could be used. Attention shall be made on the height of the beam. The fixing detail could be modified as appropriate.

Movement Joints in Bridges

In bridges, the movement joint and expansion joint are considered as types of concrete joints that fall under the same category and they use similar detailing.

It s quite common in bridges not to have movement joints as they connect with different elements usually.

Movement joints are provided to accommodate the following structural movements.

- Creep and shrinkage effects

- Thermal variation or deformations under live loads.

- Allowing lateral movement in the case of a seismic event.

We will discuss more information under the expansion joint in this article.

Contraction Joints

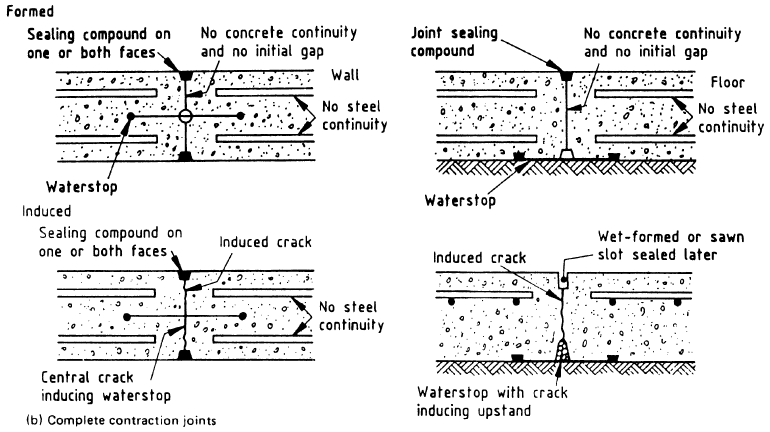

The contraction joint is a vertical joint place in a structure in such a manner that it does not affect the structural performance.

Depending on the nature of the structure, reinforcement detailing is carried out to meet the purpose of having the joint. Thus, continuation or discontinuation of reinforcement will be decided based on the structural design.

Mainly there are two types of construction joints

- Complete Contraction Joint

Types of concrete joints that completely discontinue the reinforcement and concrete are called the complete contraction joint.

Though no bending moments are transferred through the joint, shear forces can be transferred by dowel bars anchored to both blocks with one free to slide.

The spacing of the joints is specified in a way that does not allow cracking the parts of the structure. Further, adequate reinforcement is provided to transmit the applied forces from one block to another.

No gap is maintained in the contraction joint.

Water bars will be provided if the structure retains the liquids. Joint sealing could be done for any type of contraction joint.

Since there is no width for contraction joint, bituminous material could be applied on the concrete surfaces to maintain the debonding.

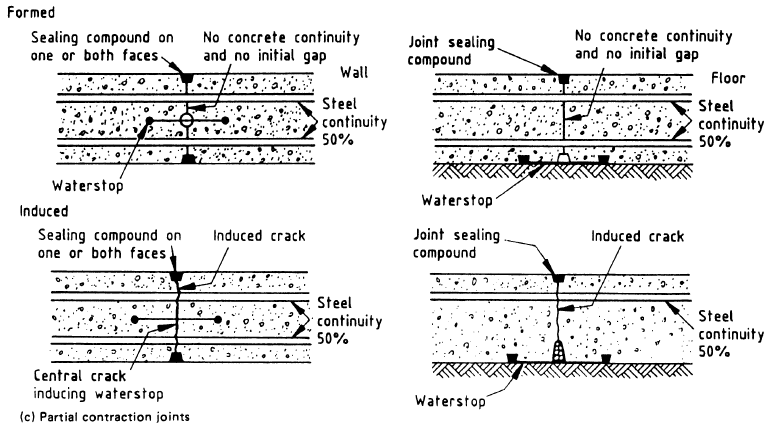

- Partial Contraction Joint

The main difference between the complete contraction joint and partial contraction joint is the partial continuation of reinforcements.

Purpose of Contraction Joint

Contraction joints are types of concrete joints that serve different purposes when compared with other types of joints.

The following advantage can be highlighted as key purposes having contraction joints in concrete.

- It avoids the random cracking in the concrete due to the contraction and expansion in the concrete.

- When large volume concrete structures such as spillways and their adjacent retaining walls are constructed, contraction joints minimize the cracking due to the thermal effects.

- Further, properly design contraction joint transfers the thrust from one block to another.

- The partial contraction joint is capable of resisting bending stresses partially.

Location of Contraction Joint

In general, contraction joints are cast where there is less bending stress or no bending stresses.

However, they can be used to transfer the thrust from one block to another.

In the case of a slab, we can provide dowels with one end free to transfer the shear forces.

Construction Details for Contraction Joints

There are typical construction details for contraction joints. The following figure indicates the contraction joint details obtained from BS 8007.

Where to use Contraction Joints

Contraction joints are widely used in floor slabs as indicated in the above figure. Formation of cracked joint or initially formed contraction joints release the stresses in the slabs due to the thermal contraction and expansions.

When we proceed with massive constructions such as hydropower or dam construction projects, contraction joints can be observed. They could be placed in retaining walls, spillway structures, etc. to avoid cracking due to the induced stresses in the concrete.

Contraction joints are widely used in concrete road construction. Construction of movement joints or expansion joints in a road increases the maintenance due to the damages with the movement of vehicles.

Expansion Joints

Joints provided allowing expansions are called the expansion joints. However, it is some times very difficult to differentiate the expansion joints and movement joints.

In this article, we concentrated on expansion joints constructed in civil construction such as buildings, bridges, roads, etc. Further, we are limited to types of concrete joints provided in concrete construction.

The following types of concrete joints (expansion joints) are discussed.

- Concrete Bridge Expansion Joints

- Concrete Road

- Roof Terrace

- Buildings Expansion Joints

Bridge Expansion Joints

Verity of expansion joints can be observed in bridge construction. Especially in continuous bridges, expansion joints are constructed to accommodate the movement of the concrete due to the thermal issues, creep effects, shrinkage effects, etc.

Generally, the bridges are constructed by connecting piers by beams and then placing the concrete deck on the beams placed between the beam constructed connecting the piers.

The only element we need to discontinue is the decking slab as others are no spanning that loans and naturally the discontinue unless were are not constructing continuous longitudinal beams in the bridge.

The following advantages can be highlighted if bridge decking expansion joints are provided.

- It accommodates the expansion and contraction caused by the change in the ambient temperature.

- It reduces the effect of shrinkage and creep

- Less possibility of cracking and buckling the bridge deck with the reduction of restrain to movements.

Bridge Expansion Joints can be categorized under three main categories.

- Small Movement Joints

- Medium Movement Joints

- Large Movement Joints

Small Movement Joints in Bridges

Mainly there are three types of small movement joints in bridges.

- Compression Seals

It provides the uniform compress and allowed the movement of the bridge deck. Further, it improves the comfort of driving across the joint.

- Silicon Sealants

Joints are cast in place and more suitable for repair works.

- Asphalt Plug Joints

Very effective in allowing the thermal movements

Medium Movement Joints in Bridge

This expansion joint type is also can be categorized under three categories based on their arrangements.

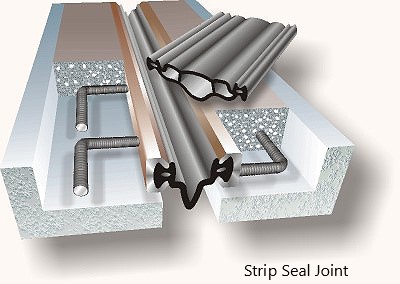

- Strip Seal Joints

A neoprene membrane fixed between strips provides the seal. Further, the membrane is not exposed to traffic. Therefore, no wearing due to the traffic will occur.

In addition, it acts as a water seal.

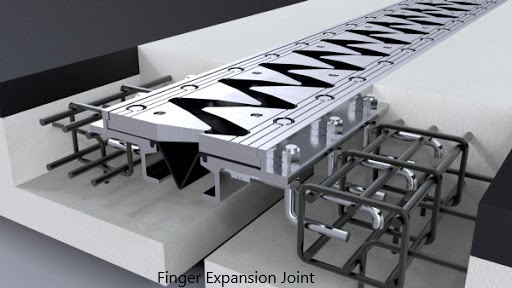

- Finger Joints

There are two segments anchored into either site, and there is a flatform to movements.

Finger joints are types of concrete joints widely used in bridge construction.

It is more durable.

- Sliding Plate Joints

Two overlapped plates accommodate the movements.

It improves the comfort for drawing, the following figure indicates similar type of arrangement.

Large Movement Joints in Bridges

The modular bridge expansion joints are mainly considered as large bridge movement joints.

However, the finger type expansion joint is also can be considered for the same category as it can be allowed a considerable amount of movement.

- Modular Bridge Expansion Joints

These types of concrete joints used to accommodate larger movements comparatively. The joint is made of steel.

Due to the arrangement of the joint, vehicles can move smoothly. Further, there is a uniform movement with the expansion and contraction of the seal.

In addition, it avoids the water leakages and falling debris through the joints and provides protection for structures below.

Concrete Road Expansion Joints

It is required to construct expansion joints in the roads at regular intervals to avoid additional stresses in the concrete due to the thermal contractions and shrinkages.

In addition, the movement to the soil under the concrete paving could also lead to the cracking of concrete if not separated by joints adequately.

The spacing of the joints is in the range of 3-5m.

Both reinforced or unreinforced concrete pavings are done. However, reinforced road pavings are more durable and crack-free for a longer duration.

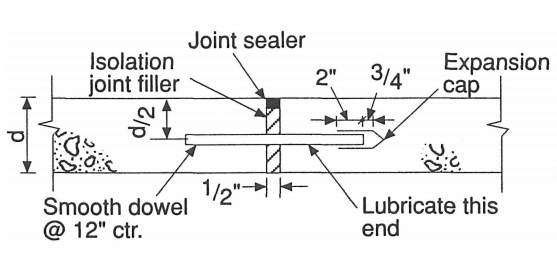

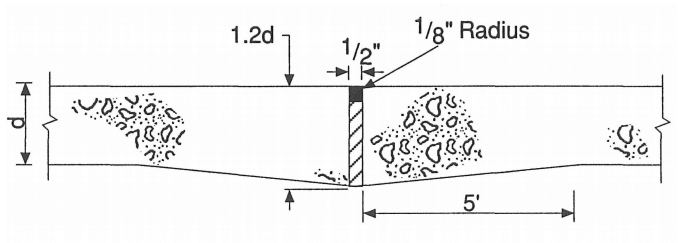

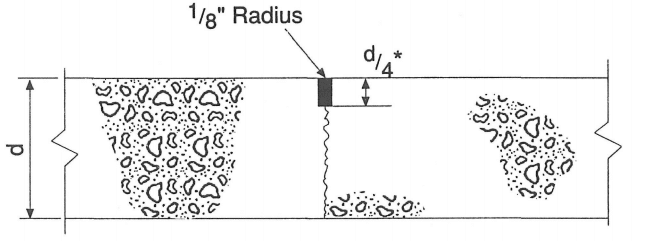

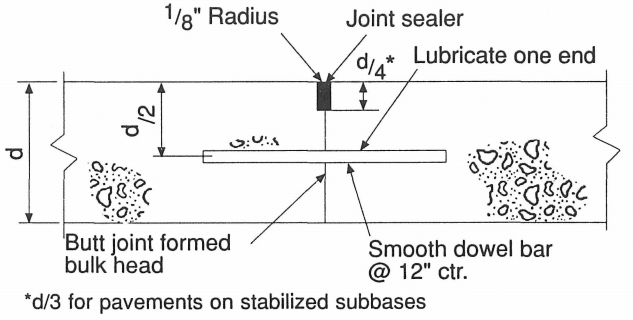

The following types of concrete joints details could be adopted in road expansion joints. Source: technical paper.

Sometimes it is observed that instead of the expansion joint, contractions joints are also constructed. Construction of the contraction joint improves the running conditions. However, it does not have sufficient width at the joint for thermal movements.

Expansion Joints in Roof Terrace

Roof expansion joints are types of concrete joints that are not mostly preferred options for allowing the movements of the structures.

However, due to unavoidable reasons, we have to construct expansion joints in roofs.

- When a building is designed as two blocks and they have different periods of vibrations. In such situations, the required width of the joint is provided.

Lateral deflection could be due to wind or earthquake events.

- When there is waterproofing, especially a membrane type, and roof insulation, it is required to place the concrete layer on the top of the insulation.

The thickness of the concrete will be around 50mm and mostly pre-fabricated mesh (BRC mesh) could be placed to avoid cracking of concrete.

Further, the dimension of the concrete is maintained around 12m2. The expansion joint is provided at every 12m2 of concrete. The width of the joint could be around 10-15mm.

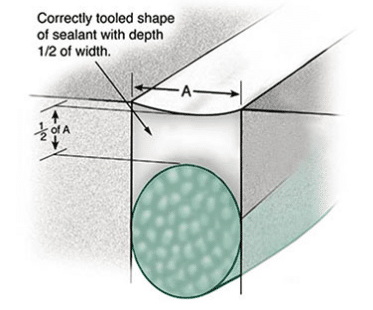

When there is a wider joint, a pre-fabricated arrangement could be used to seal the joint. If the width is in the range of 10-15mm, a suitable sealant could be used to seal the joint. M

Most widely, bituminous sealants are used for roofs as they can sustain at high-temperature levels and they are comparatively durable.

Expansion Joints in Buildings

Dimensions and the types of materials used for construction have a significant impact on the lateral movement of buildings due to the thermal expansions and contractions.

For, example, steel building expansion is greater than the concrete building.

Therefore, it is required to limit the dimensions of the structures and to provide expansion joint allowing for lateral movements.

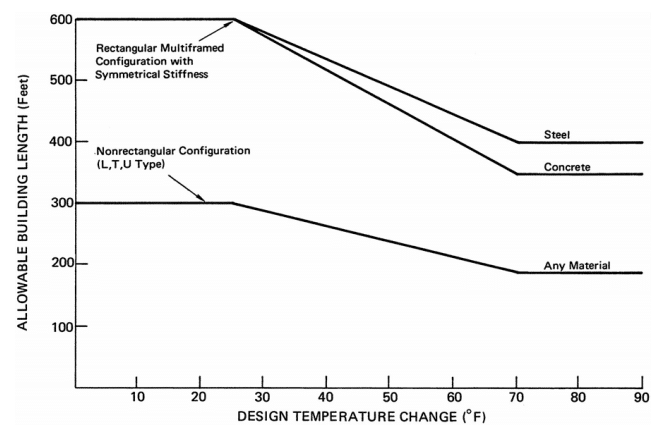

The expansion joints in buildings: Technical Report 65 published by the National Academy of Science provides a comprehensive guide on this subject.

The following figure extracted from the same guideline indicates the limitation of the joint based on the construction material and temperature variation.

It is worth studying the guide for more information and methods for calculating the building expansions.

Sliding Joints

Joints that allow the movement between two planes are known as sliding joints.

According to BS 8007, the sliding joint is the joint that allows two structural members to slide relative to one another with minimal restrains.

Complete discontinuation of the element can be observed in these types of joints. Reinforcements are discontinued and no embedment or shear keys are provided.

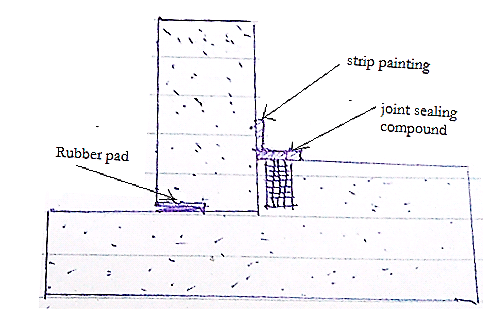

For example, a joint place in the base slab when constructing a cylinder tank can be highlighted. The following figure indicates a similar type of joint.

Further reading about the sliding joint could be made form the Gharpedia article.

Construction Joints

The most widely used type of joint is the construction joint. Almost in any construction, we need to have construction joints.

The important factor of the construction joint is how well we need to treat is when the second pour is placed.

Special attention shall be made for the construction joints cast in water retaining structures.

In addition, when there are higher bending moment and shear forces, the construction joint shall be placed avoiding these places. Further, construction joints shall be treated specially, in special structures.

Continuation of reinforcements, dowel bars, shear keys, etc. is the special feature of a construction Joint.

The article on construction joints discusses the more in detail on this subject and it is worth reading for knowing more information.

Temporary Joints

They are types of concrete joints that do not use widely in construction.

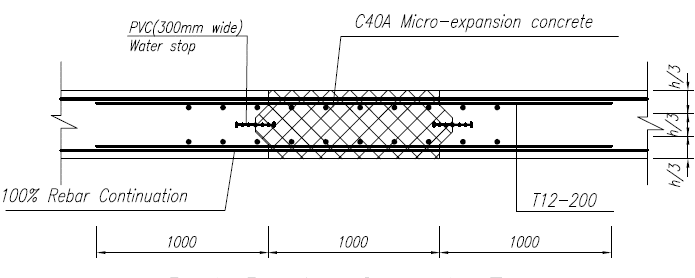

These joints are constructed in long structures whether the thermal contraction is critical especially during the construction.

A width around 1m is left for concreting is the second stage. Mostly, the reinforcement is also discontinued in the joint for allowing the lateral movement. Further, watertops are also provided if there are requirements in water tightness.

The following figure indicates a temporary joint used in construction. In the joint, reinforcements have been continued. However, depending on the nature of construction, discontinuation, and lapping the reinforcements could be done.

Isolation Joints

Isolation joints serve different purposes. It could be used to isolate the structural elements, concrete elements, and other elements such as wood, brick, steel, etc.

When it is required to allow for movement in the construction in different stages, we could have an isolation joint.

For example, if we need to have void till the construction is completed or later we need to close part of it, we may form an isolation joint.

A nib could be kept around the opening and later slab could be constructed and support on the nib.

In addition, changes in the material properties at the connection of two-element could lead to cracking. Providing a joint of this nature could minimize it.

In summary, the isolation joint is a joint kept in the structures allowing relative movements.